All in a spin

To be a good engineer, I have always maintained, in addition to an inquisitive mind and a grasp of the technology, you also need to be a student of history, for on many occasions the practices of the past give an insight into the possible problems of the future. And as all older engineers know, there is nothing like having been there the first time around to spot the problem when it next re-occurs, perhaps in another format.

To be a good engineer, I have always maintained, in addition to an inquisitive mind and a grasp of the technology, you also need to be a student of history, for on many occasions the practices of the past give an insight into the possible problems of the future. And as all older engineers know, there is nothing like having been there the first time around to spot the problem when it next re-occurs, perhaps in another format.

I was reminded of this some years ago when a recently built prototype engine had scuffed tappet faces after only a few hours' running. Noticing the condition and reassembling to continue the programme, after a further ten hours and stripping once more, rather than seeing even more surface damage, the original scuff marks were slowly beginning to fade.

Recognising the situation and understanding the precise build procedure, the issue was quickly put down to a lack of lubrication at the build stage and an unsympathetic regime when firing for the first time. The lack of lubrication during the initial running caused scuffing on the softer tappet surface when running against hardened cams. Once oil was present after only a few seconds the initial damage was slowly and steadily polished out until, after several hundred hours, no visible damage was evident at all.

That valve tappets no longer have to revolve to even out wear was evident by this exercise, but only when flooded with suitable lubricant to prevent metal-to-metal contact during the initial stages. Should these particular tappets have been allowed to rotate, I doubt any scuffing would have been observed at all. Historically, however, tappets have always been encouraged to rotate in their housing, and along with them (in overhead cam engines at least) the intake and exhaust valves beneath.

Common in many older overhead valve applications with the camshaft in the block, the tappet would be encouraged to spin by having a point of contact offset to the axis of the tappet. Rather than being completely flat, the tappet would be slightly domed with a spherical radius of 40-70 in (100-180 cm) and the cam carefully ground with a taper to match. At the designed point of contact, eccentric to the centre of the tappet bore, the offset would cause the tappet above to rotate and consequently even out any subsequent wear.

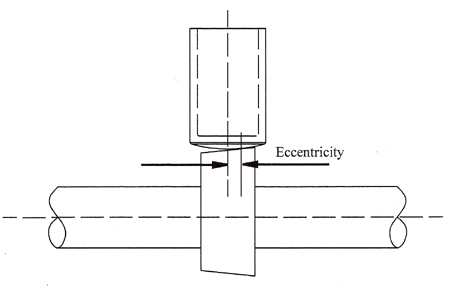

On the other hand, in overhead cam engines - particularly those intended for racing - the current trend is to have entirely flat tappets. Much easier and therefore cheaper to make, the cam can also be produced without a taper, which makes grinding a much simpler exercise as well. Mounted offset between the centre line of the tappet and that of the cam lobe, the tendency is for the tappet to spin. But even if not mounted eccentrically, the tendency (as any engineer will testify) is for the whole assembly - tappet, spring and valve - to rotate anyway, as a result of the spring introducing a slight turning force on the valve as it is compressed and the inevitable torsional vibration induced.

But if you have ever looked at any high-speed video of a complete cam/tappet/spring/valve assembly, it is difficult to conceive a situation where they cannot rotate.

Fig. 1 - Evidence of rotation on a flat tappet

Fig. 2 - Cam-in-block arrangement

Written by John Coxon