Bearing the brunt

For all of its engine bearing needs in NASCAR Camping World Truck Series (CWTS) engines, PME Engines of Mooresville, North Carolina has researched heavily to meet its main and rod end requirements.

For all of its engine bearing needs in NASCAR Camping World Truck Series (CWTS) engines, PME Engines of Mooresville, North Carolina has researched heavily to meet its main and rod end requirements.

On a mile-and-a-half oval like Chicagoland Speedway, where the CWTS raced the final weekend of August, PME owner Mark Smith acknowledged that he is “always fighting temperatures because they never lift here. They’re running wide open throttle all the time, so the temperatures are always up and you always have to control your oil temperatures. We used the tapered spacers here and they take about 200 horsepower away, giving us 8000 rpm maximum for about 700 horsepower.”

Of course with lower speeds he can play with his clearances a little bit. “It’s like all stuff; the key is making sure we keep everything cool and look at our oil flow, making sure we’re in the areas we want because you don’t want the oil to take power away,” Smith told me at Chicagoland.

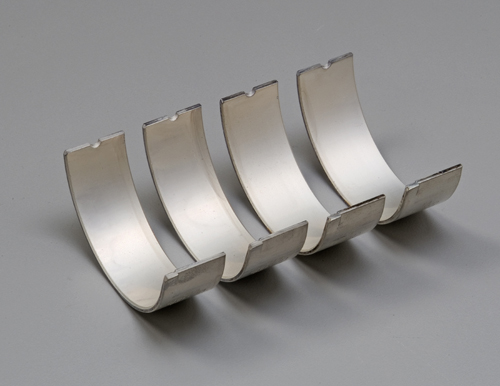

According to Bill McKnight of MAHLE Clevite, PME Engines uses the MB3229V, a 2.017-inch main set with the Vandervell lead-indium overlay. “It is very popular in NASCAR because this set allows teams to transition from the 2.017-inch shaft diameter to the 2.00-inch shaft and utilize the same block.” The mains are available in X, standard, 0.017”, 0.018”, 0.019” and 0.010” sizes and McKnight said PME usually takes trays of 25 pieces per order.

PME has experimented with bearing coatings in the past but Smith doesn’t feel it’s terribly critical now because these particular bearings he’s been using – after careful research – are “almost bullet-proof. We coat every once in a while because you always go back and try something again. But for the most part, we leave it alone and let it do its job.”

For rod end bearings, PME specifies the CB1798H, which has a 1.850-inch shaft diameter and measures 0.709-inch wide. “This H series bearing has a thin Babbitt overlay that is slightly harder than the lead-indium overlay of the V material,” McKnight said. “It also has a medium amount of eccentricity and a high level of crush, suitable to the NASCAR application for which it is intended.”

Smith says he runs his bearings for about 350-400 miles. “There’s been times when we run them a secondary time,” he revealed. “You measure the spread and you measure to make sure you still got the clearances and that the departing lines are correct. For the most part, 1000 miles is about as far as you run them.”

He appreciates the fact that his supplier is proactive with the size bearings he needs. “They have minimum diameters on the crank so they’ve come up with some new bearings that have helped us out. The housing for the con rod is a standard size now,” Smith said.

Written by Anne Proffit.