Biobutanol

Mention the word bioethanol to most people, even the ones who have little interest in our industry, and the chances are they will at least know that you are talking about alternative fuels. Added to gasoline fuel in amounts up to 98% of the total, the process of adding ethanol derived from bio sources to spark ignition fuels can reduce the so-called 'carbon footprint' making our sport, or so we try to convince others, more politically acceptable to all. The real benefit to us performance types, as we all probably know by now, is that with higher detonation resistance and richer mixtures we can expect to extract just that little bit extra performance at the same time.

Mention the word bioethanol to most people, even the ones who have little interest in our industry, and the chances are they will at least know that you are talking about alternative fuels. Added to gasoline fuel in amounts up to 98% of the total, the process of adding ethanol derived from bio sources to spark ignition fuels can reduce the so-called 'carbon footprint' making our sport, or so we try to convince others, more politically acceptable to all. The real benefit to us performance types, as we all probably know by now, is that with higher detonation resistance and richer mixtures we can expect to extract just that little bit extra performance at the same time.

Mention the word 'biobutanol,' however and you will be surely met by any number of blank looks and quizzical expressions. But before long there is every chance that biobutanol may be on the lips of every tree-hugging politician in the land if recent developments in fuels technology come to full fruition.

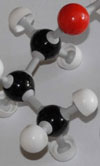

To the chemists amongst you butanol, or to use its chemical formula, C4H9OH is the fourth in the series of simple alcohols: methanol, ethanol, propanol and now butanol. Currently derived mainly from the fermentation of sugars in organic feedstocks such as sugar cane/beet, corn or wheat, the future suggests that with only small changes, the same second and third generation manufacturing plants can be used as those for bioethanol.

With four carbon atoms in the molecule, biobutanol has a much higher energy content per litre than ethanol. To the farmer this means a more valuable crop and hopefully higher prices. To the fuel chemist, an energy density of 29.2MJ/L compared to that of 19.6 MJ/L for ethanol and 32 MJ/kg for gasoline is a much more practical proposition for blending into current day fuels. So as bioethanol fuels require bigger fuel injectors and larger fuel tanks, biobutanol blends, in theory at least should be able to use the same gasoline systems currently used. Being less corrosive than bioethanol such systems wouldn't necessarily have to be so highly specified against corrosion, while at the same time it is also less aggressive towards elastomer seals.

But as they say, you can't have everything and while the Octane numbers of the substance are broadly comparable with that of a high performance gasoline, it is the relatively poor (compared to ethanol) heat of vaporisation, which begins to let the side down. At around 0.43 MJ/kg compared with 0.36 MJ/kg for gasoline and a whopping 0.92 MJ/kg for ethanol, the opportunity to keep charge temperatures to an absolute minimum, especially in turbocharged engines, is lost.

The big advantage of biobutanol in a strange way however is its low vapour pressure. Let me explain. Gasoline fuels are blended from a wide range of hydrocarbons to produce a fuel that gives easy starting in cold temperatures but good fuel economy at higher ambient temperatures. The fuel therefore has a range of individual fuel boiling points, which make up a typical fuel volatility curve. When blended into gasoline on its own, biobutanol could seriously distort this curve producing poor cold start performance. However, our old friend bioethanol has quite the opposite effect when only small amounts of the product (less than 10%) can have a major influence on the light end of this curve. By combining the effect of the bioethanol with that of biobutanol this distortion can be minimised and therefore biobutanol is said to have co-synergy with gasoline fuels containing bioethanol.

At the moment the use of biobutanol as a blended component into gasoline is still in its infancy. While it is still only early days there is every chance however that the technology may see the continued use of gasoline type fuels well into the foreseeable future. And while we won't necessarily get all the benefits accrued from ethanol based fuels, as far as most users will be concerned, nothing will have changed.

Is that not good news for all this New Year?

Fig. 1 - Primary butanol models.

Written by John Coxon