Biofuel results

Trelleborg Sealing Solutions, a leading multi-national manufacturer of gaskets and seals, has published research into the interaction of sealing compounds with biofuels which will cause fuel system designers to rethink material selection for sealing gaskets and o-rings.Trelleborg evaluated the compatibility of typical automotive biofuels for both gasoline and diesel engines with a variety of fuel system sealing compounds, focusing on hardness, stress-strain and volume swelling.Initially they conducted standard laboratory tests, which suggested that typical elastomers of Fluorocarbon (FKM) and Flourosilicone (FVMQ) were compatible with commonly used biofuels.

Trelleborg Sealing Solutions, a leading multi-national manufacturer of gaskets and seals, has published research into the interaction of sealing compounds with biofuels which will cause fuel system designers to rethink material selection for sealing gaskets and o-rings.Trelleborg evaluated the compatibility of typical automotive biofuels for both gasoline and diesel engines with a variety of fuel system sealing compounds, focusing on hardness, stress-strain and volume swelling.Initially they conducted standard laboratory tests, which suggested that typical elastomers of Fluorocarbon (FKM) and Flourosilicone (FVMQ) were compatible with commonly used biofuels.

The following fuels were tested – they represent typical automotive fuels for diesel and gasoline engines:

| Test Fuel |

Description |

| DIESEL |

EN590 |

| B30 |

Diesel with 30% biodiesel (RME) |

| E22 |

Fuel C with 22% ethanol |

| E85 |

Fuel C with 85% ethanol |

| FAM B |

DIN 51604, 84.5% FAM A, 15% methanol, 0.5% water |

| RME |

= |

Rapeseed oil, methyl ester |

| Fuel C |

= |

50% toluene, 50% isooctane |

| FAM A |

= |

DIN 51604, 50% toluene, 30% isooctane, 15% diisobutylene, 5% methanol |

Figure 1: Fuels EvaluatedThe following compounds were evaluated – all are used in automotive fuel systems:

| Ref |

Description |

TR10 (°C) |

Application |

| Diesel |

Gasoline |

| 1 |

FVMQ (fluorosilicone), peroxide cure

Preferred application: diesel fuel connectors |

-60 |

* |

|

| 2 |

FKM (fluorocarbon) copolymer, 66%F, bisphenol cure (B)

Preferred application: diesel and gasoline fuel connectors |

-15 |

* |

* |

| 3 |

FKM terpolymer, 66%F, bisphenol cure (B)

Preferred application: gasoline fuel injectors |

-18 |

|

* |

| 4 |

FKM terpolymer, 68.6% F, bisphenol cure (B)

Preferred application: diesel pumps |

-13 |

* |

|

| 5 |

FKM terpolymer, 70% F, bisphenol cure (B)

Preferred application: diesel and gasoline fuel connectors |

-7 |

* |

* |

| 6 |

FKM tetrapolymer, 68% F, peroxide cure (P)

Preferred application: diesel pumps |

-16 |

* |

|

| 7 |

FKM tetrapolymer, 64% F, peroxide cure (P)

Preferred application: diesel and gasoline, low pressure fuel injectors |

-29 |

* |

* |

| 8 |

FKM tetrapolymer, 64% F, peroxide cure (P)

Preferred application: gasoline, high pressure fuel injectors |

-29 |

|

* |

| 9 |

FKM pentapolymer, 65% F, peroxide cure (P)

Preferred application: diesel and gasoline, high pressure, low temperature fuel injectors |

-40 |

* |

* |

F= Fluorine contentFigure 2: Compounds EvaluatedDiesel and B30

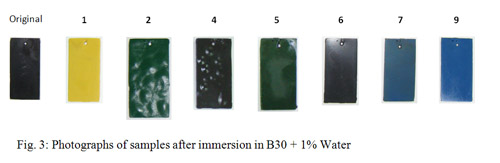

Standard tests involved immersion of the seven diesel compounds in both fuels (diesel and B30) for 336 hours at 150°C.

All compounds seemed to perform acceptably. Volume swell was well under 10% for all compounds, hardness reduction was under 5% for everything other than FVMQ (8%), tensile strength reduction was 25% or under for all compounds and the reduction in elongation was under 20% for all compounds except FVMQ, which was 26% in B30.

Water is a common contaminant in diesel fuel; typically it exists as a discrete phase at the bottom of storage tanks. It is significantly more soluble in biodiesel than in conventional diesel so there is an increased risk of water contamination.

The original tests were then repeated but using B30 contaminated with 1% water. The results showed a large deterioration in properties for all bisphenol cured FKM’s, i.e. compound refs 2, 4 & 5. These suffered volume swells of 77%, 23% and 61% respectively. The reduction in hardness was markedly increased too; FVMQ showed a 32% reduction , whilst compound refs 2, 4 & 5 reduced by 23%, 14% and 22% respectively. Reduction in tensile strength was a similar story. The FVMQ samples cracked before they could be tested, whilst compound refs 2, 4 & 5 showed reductions of 56%, 38% and 54% respectively.

The reduction in properties is due to the formation of carboxylic acids which have a significant degenerative effect on the metal oxide containing FKM’s, such as the bisphenol vulcanized compounds.

What Trelleborg have shown is that it is very important to consider water contamination in diesel fuel and to carry out appropriate material investigations.