Burning the cap

The Pro Stock contingent of National Hot Rod Association Full Throttle Drag Racing competitors has always had a problem with pushrods: they just can’t find a way to stop them from burning up, particularly at the cap.

The Pro Stock contingent of National Hot Rod Association Full Throttle Drag Racing competitors has always had a problem with pushrods: they just can’t find a way to stop them from burning up, particularly at the cap.

For two years, Terry Manton of Manton Pushrods in Lake Elsinore, California has been working to find a solution to stop these burn-up difficulties. “It’s been two years worth of study and testing and nothing solved the problem until now. Those pushrod tips were just burning up continuously,” he said.

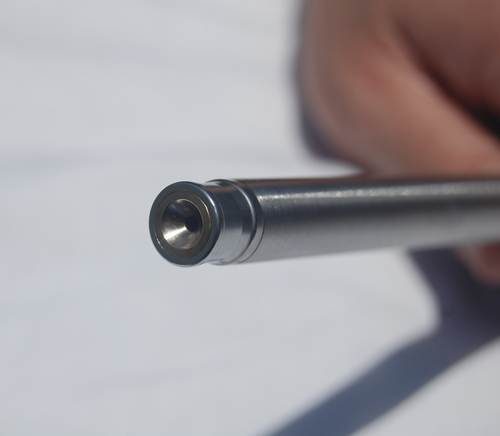

Manton believes he has now found the solution with a new, very high-grade hybrid copper that does not include beryllium material, he told us. “We’ve got a new copper insert for the top of the pushrod cap that allows the Pro Stock teams to use a 281 thou ball adjusting screw, without burning up the pushrod top and the adjusting screw. That’s always been a big, big problem with these machines,” Manton said.

“One other attached component to this pushrod solution for the Pro Stock racers is the new tool steel adjusting screws that complement the copper cup insert,” Manton explained. Of course, the final surface hardening treatment applied to this adjusting screw is a compound he’s keeping close to the vest. The new part has only been in use since the beginning of April and was first tested on a dynamometer by Kurt Johnson, son of Warren Johnson. “It looks better than anything we’ve used before,” Johnson said. Kurt and Warren Johnson are using the piece, as is Greg Stanfield, David Nickens and V Gaines.

Because they can use dynos to test and measure their engines, unlike the nitro-burning cars in Top Fuel and Funny Car, Pro Stock teams are constantly trying new options between races. “We really don’t know yet how long these pushrods will last because they still haven’t burnt them up, even with all the testing these guys do between races,” according to Manton. “It’s all about the copper insert in the pushrod tip; that is what makes the biggest difference,” Manton said. “The teams are reporting increases of five to seven horsepower and less friction at the adjusting screw contact area.”

Seven drivers have been using the new product, which fits all 3/8-9/16-inch pushrod diameters in use for the Pro Stock category. “It is still so new that we do not yet have a good amount of information on the product, but so far, everything appears to be working extremely well and we are very excited about it.”

Written by Anne Proffit.