Bearing the load

In most motorsport applications, bearings have had to cope with increasing loads as the requirements for higher performance of engine, gearbox and suspension components continues to increase.

In most motorsport applications, bearings have had to cope with increasing loads as the requirements for higher performance of engine, gearbox and suspension components continues to increase.

Recalling his days at Tyrrell, Renault's Formula One chief designer Tim Densham says, "Normally you would just open the SKF book and pick out standard bearings for most of the shafts." Things have moved on somewhat from those days, although even then some companies did make custom bearings for the teams.

Rule changes have played an important role in modern bearing materials in Formula One and, although introduced several years ago, the use of ceramic bearings is now more important than ever - where permitted. Christian Klatt, vice-president of sales at German ceramic bearing manufacturer Cerobear, says, "At least one component is always made from ceramics - typically the rolling elements, the balls or the rollers, and the races are made from special steel which is more advanced than conventional bearing steel."

Standard bearing steel, 100Cr6, is good for most bearing applications, and its quality has improved even in recent years through better cleanliness. But depending on the application or requirement, there are improved bearing steel grades available that offer better temperature resistance, corrosion resistance and particularly fatigue life.

In motorsport - perhaps more than in any other application - weight and space are critical and, as a result, bearings are operated at Hertzian stress levels that one would never see in industrial applications, sometimes above their static load capacity. So there is a demand for higher grade bearing steels in motor-sport (such as Cronidur 30 and X 40 CrMoVN 16 2) that enable designers to downsize the bearings, maintaining the same service life or even increasing it.

High Nitrogen Steels (HNS), which have a higher nitrogen content and a lower carbon content, were introduced into motorsport bearing applications in 1999. They have fewer carbides, and carbides have a positive effect, giving strength to the material. On the other hand, if they are too big and their proportion in the structure is too high, they can act as sources of fatigue failure.

Hybrid ceramic/steel bearings have outperformed standard bearings in various tests that show a ten- to 100-fold improvement in service life, depending on the testing conditions. But in Formula One in particular there has always been a demand for improved solutions, so research is being carried out to develop a new bearing steel that is even better than HNS.

With steels, however, 'superiority' does not necessarily mean greater hardness for them to be better. HNS (HRC 58-60) provides the same or an even lower hardness than 100Cr6 (HRC 58-62), but it is the structure and its resistance to Hertzian stresses that is important, so it is this that has been the focus of development to achieve a material with a superior, finer and more homogeneous structure. The result should be a better wear and overrolling resistance; (this is resistance against being rolled over, as opposed to rolling resistance which is friction), which results in a longer fatigue life, particularly under compromised lubrication conditions.

Brittleness could be the downside, although this is not yet proven but still likely, as brittleness in steels often rises with hardness, which is why the development of this new steel is aiming for a finer structure, as this would reduce brittleness. But brittleness in general would not pose any problems for rolling elements in hybrid bearings and plain races in ceramic bearings, although this would not be recommended for some special types of highly loaded flanged bearing races that depend on the load and geometry of the application. Si3N4 balls are used in highly shock-loaded applications such as wheel bearings, gearbox and diff bearings, with very few problems.

It would be wrong therefore to give the impression that operating hybrid bearings is a risk because the materials are brittle. If this were the case, ceramic bearings would not be used in applications from Formula One to the Space Shuttle's main engine.

Current Formula One rules require that a gearbox is run over four races before it can be replaced, so it is important to know that the unit will last the course. As there is no testing allowed, a used 'box may be installed for Friday practice but, according to Densham, bearing failures are not unheard of.

Densham says, "We have had several analyses done on the bearing loads and we know which ones are the heavily loaded ones. If you have a problem, the first thing is to squirt a bit more oil in there, and that is something we can do quickly, whereas to have a new bearing made takes a fair amount of time."

Fig. 1 - Double-row crankshaft bearing

Fig. 2 - Flanged hybrid bearings

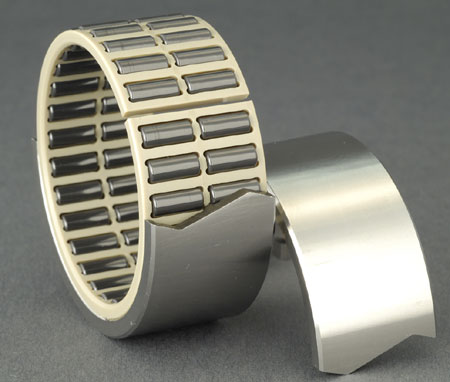

Fig. 3 - Selection of needle and roller bearings for engine, differential and gearbox

Fig. 4 - Valvetrain bearings

Written by Glen Smale