Desmodromic or demonic?

I don't know about you but when I was young, my written command of the English language was, shall we say, a bit lacking. "Needs to pay more attention to his spelling," was the end-of-year comment by one of my English teachers. But despite my best efforts - or possibly because of them - a future in the engineering professions seemed to beckon. I mention this because to me the best invention over the past 20 years or so has been the autocorrect option in wordprocessing software or the predictive text mode on my phone. Thus, when I started to type the word 'desmodromic' into my laptop, up popped the word 'demonic'.

I don't know about you but when I was young, my written command of the English language was, shall we say, a bit lacking. "Needs to pay more attention to his spelling," was the end-of-year comment by one of my English teachers. But despite my best efforts - or possibly because of them - a future in the engineering professions seemed to beckon. I mention this because to me the best invention over the past 20 years or so has been the autocorrect option in wordprocessing software or the predictive text mode on my phone. Thus, when I started to type the word 'desmodromic' into my laptop, up popped the word 'demonic'.

To many (except perhaps Ducati owners) the word 'desmodromic' will mean very little. A remnant of a bygone age when valve spring technology was still in its infancy, desmodromic valve gear used one cam to open the valve and another, wholly separate from it, to close it again. The valve spring, if you like, was made redundant, and in theory at least this enabled valves to open and close much quicker, or the engine to rev much higher than would otherwise be possible. But for the arrival of the pneumatic valve system, pioneered by Renault in Formula One, 'desmo' systems might now be much more common. However, improved valve system modelling has given us a better understanding of valvetrain dynamics and, together with better valve springs, has effectively sidelined desmodromic technology - at least for the time being.

In traditional valvetrain systems, as the engine speed increases, sooner or later the momentum of the valve and tappet assembly will overcome the ability of the spring to control it. At this point - graphically referred to as 'valve float - at best the valve can land heavily on the closing flank of the cam, producing abnormal wear and valve bounce, or at worst catastrophic engine failure as a result of piston-to-valve contact. Either way, and somewhat of an understatement, the engine's durability will be impaired. In removing the spring and having a separate cam for closing, as well as the one for opening, this limitation of valve float is reduced, and valvetrain mechanisms can be designed to give faster opening and closing velocities.

The use of desmodromic valve gear doesn't, however, do away with springs altogether. In a practical engine, when the valve has to be fully closed in order to develop compression in the cylinder, light 'helper' springs have to be provided. But turning a desmodromic engine over by hand at slow speed reveals that these systems have very low friction at low speed, unlike traditional sprung valves.

Traditional valvetrains have very high torque requirements at low speed, which steadily fall as the boundary layer lubrication slowly morphs into that of hydrodynamic lubrication with increasing engine speed. Desmodromic systems, on the other hand, start by having very low friction at slow speeds, which steadily increases as the engine revs rise. For maximum fuel economy, friction and engine speeds will need to be kept low, and so in the relentless search for ever improving fuel economy, desmodromic valve trains may yet see a resurgence.

Desmodromic or demonic? I'll let the reader decide, but wouldn't it be nice if mechanisms like these were more common?

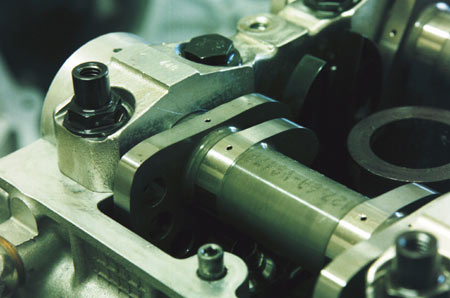

Fig. 1 - Ducati MotoGP desmodronic valve gear

Written by John Coxon