Variable Duration Camshafts

Given enough time in engine research and development, only someone who is very blinkered could say they've never come across something a bit, shall we say, unusual. Devices to increase fuel economy substantially tend to be the norm here. Now and again I get a full-size drawing of an engine concept, and invariably the sender is looking for introductions or funding. This month, however, I have a camshaft, and for once its owner/designer has sent me the actual component, which looks interesting.

Given enough time in engine research and development, only someone who is very blinkered could say they've never come across something a bit, shall we say, unusual. Devices to increase fuel economy substantially tend to be the norm here. Now and again I get a full-size drawing of an engine concept, and invariably the sender is looking for introductions or funding. This month, however, I have a camshaft, and for once its owner/designer has sent me the actual component, which looks interesting.

The idea comes from Danny Williams, of New South Wales, Australia, who has applied some ingenuity and a lot of hard work to come up with a variable duration camshaft that maintains the opening and closing characteristics - velocity, acceleration and jerk - of a traditional engine camshaft, but which changes the phasing at which these occur.

In essence, he has taken an opening flank and a closing flank and joined them together with a 'bridge' that keeps the valve open for a variable period of time. Calling it a 'helical' cam, he not only designed it but built one to test in a Suzuki 250 GSX, in which it has run on the bench only, for about 15 hours.

Now I have to say that it is a lot easier to play with the device than describe its action, but described by Williams as a 'coaxial shaft, combined profile cam', the unit consists of two shafts, one inside another.

The outer shaft carries with it the normal cam opening profile at one end which, as we travel along its length in the axial direction, blends into a lobe of constant radius. The inner shaft moves in and out co-axially and has the closing flank and ramps attached to it (see Figs. 1 and 2).

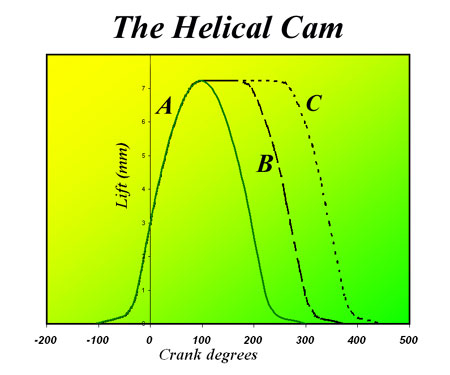

As the two shafts move relative to each other at one end of the cam, the profile is that of profile A in the drawing here (Fig. 3), while at the other end profile C is followed. At one end the duration is about 240 crank degrees; at the other about 320.

The interesting point about this cam is that, as the inner shaft moves and rotates, the period of opening - the duration - is continuous and directly proportional to the position along the axial width of the main cam. Suitable only for a finger-follower system, in this particular example the drive comes in through the centre from a roller chain and sprocket assembly.

In theory, the valve dynamics are little changed from the standard GSX profile - apart from the extra accelerations and jerks caused by the constant lift portion of the curve - but the main concern would appear to be the apparent complexity of the assembly process and the accuracy of the fit of the sliding parts required during manufacture.

The angle of helix in this example is about 30º, and obviously the wider the main cam or the shorter the change in duration then the less this angle would be. But in trying to make this as compact as possible, the risk must surely be in the mechanism jamming. Williams, however, assures me that this is not the case in practice.

It's a refreshingly simple approach and one that would be good to evaluate on a dyno, despite the difficulties and costs associated with manufacturing it. But what do you think?

Fig. 1 - Closing flank at a mid-position slides along between the end of the nose and the beginning of the base circle

Fig. 2 - Another view

Fig. 3 - Cam profiles(s)

Written by John Coxon