Why not titanium?

There are some materials regulations in motor racing that don't make sense, because they stifle development and outlaw materials which just make good sense. The ban by many race series on the use of magnesium is one example of this, given that it has always been an affordable material and is common in series production. I imagine that many of those who write such rules drive around in cars with engines using magnesium. Materials are often consigned to this fate when they are judged to be expensive and 'exotic'.

There are some materials regulations in motor racing that don't make sense, because they stifle development and outlaw materials which just make good sense. The ban by many race series on the use of magnesium is one example of this, given that it has always been an affordable material and is common in series production. I imagine that many of those who write such rules drive around in cars with engines using magnesium. Materials are often consigned to this fate when they are judged to be expensive and 'exotic'.

Then there are other regulations that outlaw materials which nobody would choose to use anyway. It is into this category that titanium falls when being considered for crankshafts. There are stories that, a couple of decades ago, someone tried (unsuccessfully) to make a titanium crankshaft for Formula One racing. I have no doubt that it is entirely possible to make such a component, but what I seriously doubt is whether it would represent any improvement over a steel crankshaft. There are a number of reasons for this.

Titanium is notoriously poor in sliding contact. Indeed, steel is nitrided for wear resistance in highly loaded crankshafts. Titanium would need some very special surface treatments to allow it to run successfully without suffering serious wear in a very short time. For the sake of argument, let us assume that we are able to overcome this hurdle using a combination of treatments.

While there are a number of high-stress points in a crankshaft - fillet radii and oil drilling exits being prime examples - an important aspect of the design process is to consider the stiffness of the component. This, in addition to other design variables and component masses, has an effect on the torsional behaviour of the crankshaft system and dictates the critical torsional frequencies.

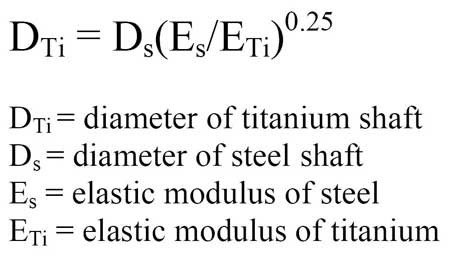

If a steel crankshaft had been optimised in this respect and the requirement for a titanium crankshaft would therefore be to match the stiffness, it would need to be much larger in diameter. In terms of torsional stiffness, the product of the shear modulus and the second moment of area needs to be matched. In choosing titanium, this can be done easily, as the second moment of area is proportional to the fourth power of diameter. Shear modulus is proportional to elastic modulus, and to match the shear rigidity of a steel shaft - the product of shear modulus and second moment of area - the diameter of the titanium shaft needs to be greater, according to the following equation:

We will find that the titanium shaft needs to be about 16% larger than the equivalent steel shaft to maintain torsional rigidity, and therefore the titanium shaft has 35% greater area. The product of area and density gives the titanium shaft a 24% lower mass, so it appears to be an attractive material, if the surface can be treated such that it will last in a race engine.

However, the real disadvantages come when considering the effect on other components. As a consequence, the bearing surface speeds are 16% higher. In terms of friction this is a big disadvantage, and affects both the big-end and main bearings.

The big end of the con rod needs house bearings sized to accommodate a 16% larger crankpin. The means a much heavier con rod, and by moving the rod bolts further away from the applied load means they have a greater component of bending. This, along with other design changes to the con rod, may necessitate a redesign of the bolt.

It is common, certainly in the case of 'vee' engines, that the lowest point of the con rod locus is defined by the head of the con rod fastener. By moving this away from the crankpin centreline, the locus sweeps lower in the crankcase, reducing clearance to the floor, and in the case of some highly optimised engines, this would require a deeper sump and moving the whole engine up in the car.

Titanium is an attractive material, but as the saying goes, we need to 'pick our battles carefully' when we look to substitute steel for titanium.

Fig. 1 - Formula One crankshafts have small bearings to reduce friction and a low crankshaft centreline height. It is unlikely that using titanium for crankshafts would be considered

Written by Wayne Ward