Additive manufacturing using metals

The proliferation and benefits of additive manufacturing (AM), or 3D printing as it is now more commonly known, has enabled it to find favour across multiple industries. Formula One is no exception, with the sport consistently being one of the earliest adopters and hardest driver of new technologies in its continual search for performance gains.

3D printing with polymers has been available for more than 20 years and has been used by Formula One engineers, but if you exclude the fibre-reinforced polymer composites that make up most of a modern racecar, plastics have only limited applications on the car itself.

In general, printed plastic parts have been used predominantly for mock-ups and space claim (the use of a model to represent the overall dimensions of a component, but generally without functionality, to allow other components to be designed and added to the system without interfering with existing parts), wind tunnel models and more recently for tooling in the production of components from composites. The limited structural capabilities and temperature resistance generally restrict the selection of polymers, whether 3D printed or produced via more conventional methods; however, the geometric freedom unlocked by AM and the potential advantages this can deliver make it a technology that will continue to find applications in Formula One.

This is supported by more recent developments in AM which have seen the increasing availability and capability of metallic 3D printing. This opens up a world of opportunities with the ability to rapidly manufacture components in high-performance alloys such as Inconel, a nickel-chromium superalloy, and 6Al4V titanium alloy, both commonly used in machined, cast and fabricated motorsport parts.

These opportunities have not gone unnoticed by the Formula One engineering fraternity, and techniques such as direct laser metal sintering (DLMS) and laser melting are being exploited to deliver a range of benefits that are not solely concerned with reducing weight. In fact, it is often the ability to reduce development times that make these techniques so attractive, although unsurprisingly this can come at a cost.

Some examples of metallic AM components include turbine housings that form part of the current turbo powertrain ERS systems, and at least one team has used DLMS to produce fully functional prototype housings in steel for development and testing. The parts were post-machined, as would be required for a more conventional cast version, but the build resolution and material properties offered by this technology allowed the wall thickness to be reduced by a third, from 3 to 2 mm.

The reduction in lead time and weight is significant, especially when considering the additional patterns and tooling required for casting, but with a price tag of around £20,000 (about $32,000) per housing the metal printing technology is currently still too expensive for the limited ‘production’ required by Formula One teams, even with their budgets.

Other teams have been developing titanium valve bodies for shock absorbers, and by optimising the component geometry for the printing process and understanding the design freedom and limitations, significant returns are possible.

Ongoing r&d into the printing of metallic honeycomb structures may also have some applications in motorsport. The prospect of printing cores for fibre-reinforced composite structures could offer some interesting properties, especially in crushable structures, as the core can be engineered to behave auxetically (exhibiting a negative Poisson’s ratio), potentially increasing its ability to absorb energy. (Poisson’s ratio is the negative ratio of transverse to axial strain. When a material with a positive Poisson’s ratio is compressed in one direction it tends to expand in the other two directions perpendicular to the direction of the applied force. An auxetic material, which has a negative Poisson’s ratio, exhibits the opposite behaviour, and when compressed in one direction become thinner in the perpendicular directions.

Metallic AM parts have generally exhibited properties exceeding those of equivalent cast materials, but which fall short of the performance offered by the alloys in wrought form. The continual and rapid developments in these technologies are beginning to address this deficit though, as well as improving build resolution and surface finish.

Heat treatments for annealing and stress relief of titanium are delivering improved ductility and fatigue strength, while solution treatment and precipitation hardening (ageing) of Inconel offer improved mechanical properties, making these materials a viable alternative to machining from solid wrought alloys.

As the cost of the raw powdered alloys and machines decrease, and the capability, capacity and availability increase, the use of 3D printed components on Formula One cars will continue to rise. The early compromises regarding material properties and build resolution (wall thicknesses of 150 microns are achievable) are being addressed, offering the potential to take metallic AM technology from its niche applications in prototypes and complex integrated geometry designs to a production alternative for the small batch volumes required in Formula One.

Near-net shape printing with minimal post-machining could offer racing significant advantages in development and production times and ultimate costs, as well as all the potential performance gains that can be achieved once freed from the geometry constraints of conventional manufacturing techniques.

|

Material

|

Density

? (g/mm3)

|

Modulus

E (GPa)

|

Tensile strength

s (MPa)

|

Fatigue strength s (MPa)

|

Elongation (%)

|

|

Inconel 718 (annealed & aged condition)

|

0.00820

|

200

|

1360

|

485

|

20

|

|

Titanium 6Al 4V (annealed)

|

0.00447

|

114

|

1000

|

600

|

18

|

Mechanical properties of wrought materials

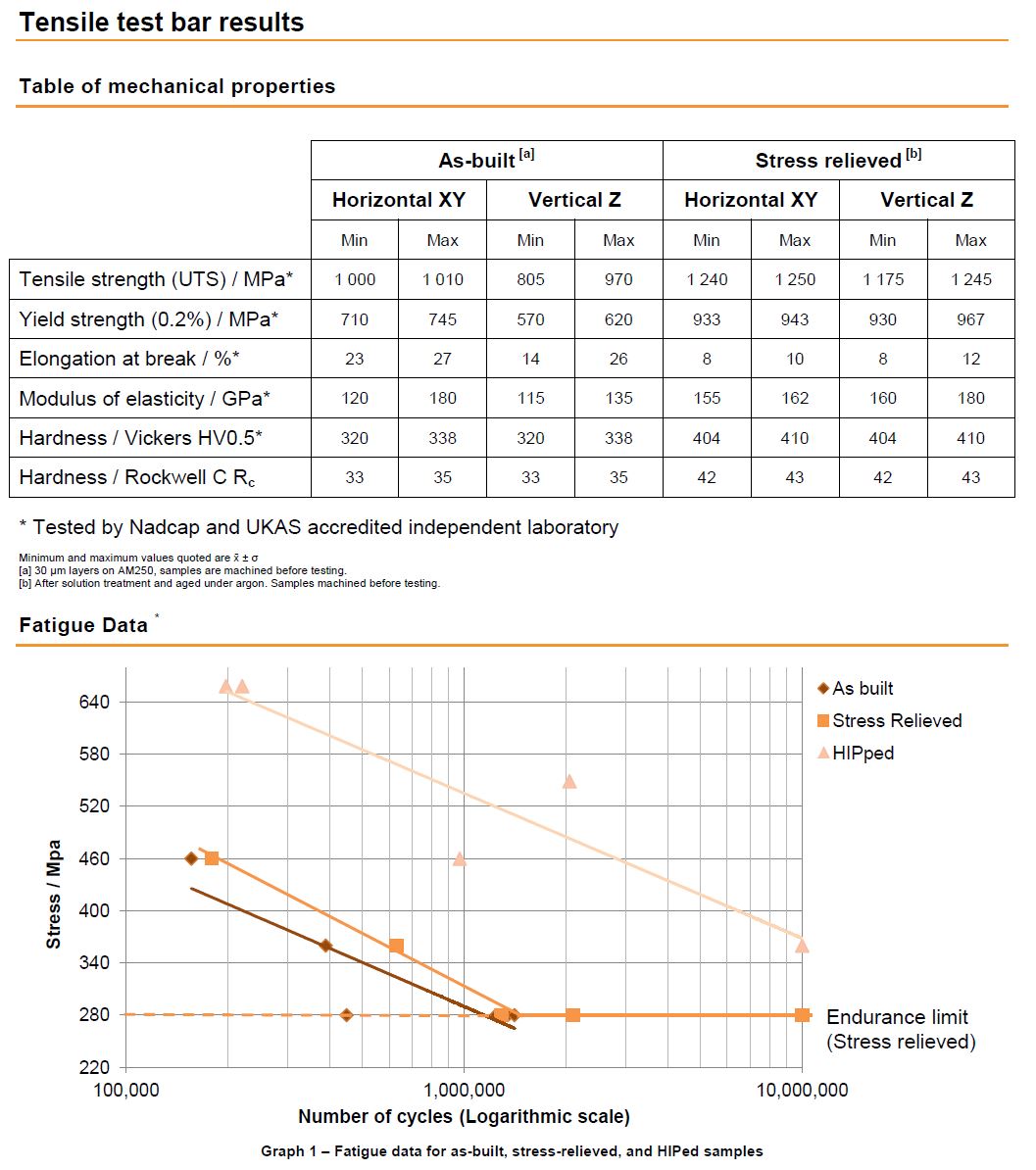

Table of AM mechanical properties (Courtesy of Renishaw)

Table of AM mechanical properties (Courtesy of Renishaw)

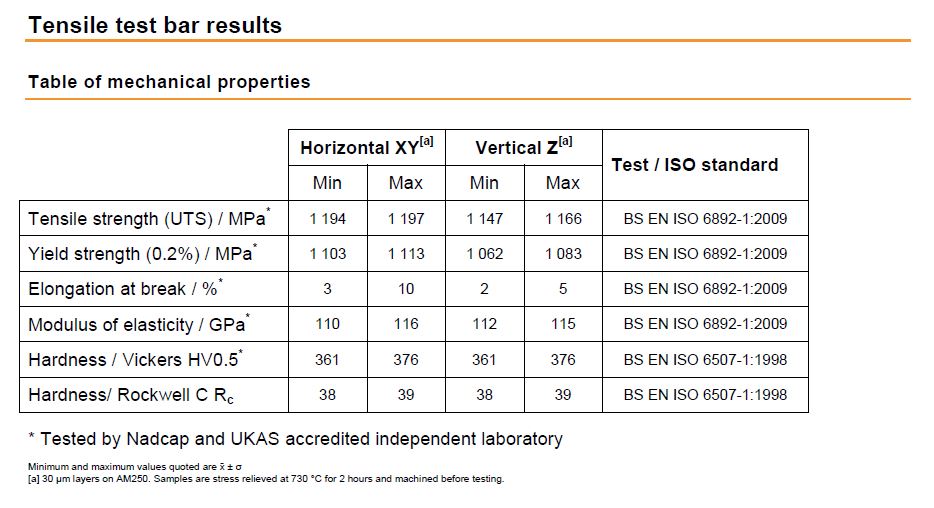

Table of mechanical properties of titanium 6Al-4V-AM (Courtesy of Renishaw)

Table of mechanical properties of titanium 6Al-4V-AM (Courtesy of Renishaw)

Written by Dan Fleetcroft