The wiring harness

If the ECU can somehow be considered as the brain of the engine then I guess the wiring harness is roughly equivalent to the rest of the nervous system. In humans and other animals, receptors in the skin send impulses to the brain via dendrites and the nerves. These impulses are then reconfigured and sent back to the muscles to produce some form of movement. And while great care is taken to ensure that the body's nervous system is not overstressed or abused, likewise shouldn't we look after our wiring harness in the same cosseting manner? And yet how often do we see the wiring harness in some competition vehicles looking little better than the proverbial rat's nest (hopefully minus the rat, of course)?

If the ECU can somehow be considered as the brain of the engine then I guess the wiring harness is roughly equivalent to the rest of the nervous system. In humans and other animals, receptors in the skin send impulses to the brain via dendrites and the nerves. These impulses are then reconfigured and sent back to the muscles to produce some form of movement. And while great care is taken to ensure that the body's nervous system is not overstressed or abused, likewise shouldn't we look after our wiring harness in the same cosseting manner? And yet how often do we see the wiring harness in some competition vehicles looking little better than the proverbial rat's nest (hopefully minus the rat, of course)?

By its very function, the engine wiring harness will reside in some of the most demanding environments within the vehicle. Subject to extremes of temperature and vibration, and occasionally doused in aggressive fluids, it not only has to be robust and flexible in equal measure but not too heavy either, since like any other component in a racecar its weight should be at a minimum. I recently measured the weight of a simple aftermarket harness and was surprised to find that the wiring alone, without any of the connectors, amounted to more than 1.5 kg or almost 3.5 lb! In my case, careful re-routing around the engine bay will hopefully bring this figure down but this would again appear to be a typical example of how components that many of us generally ignore at the design stage can easily catch us out later on.

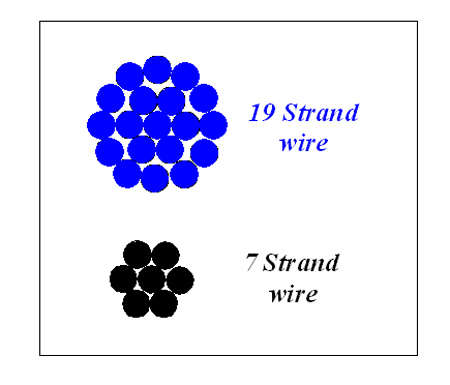

When it comes to wiring, flexibility and robustness are the opposites of the same issue. Whereas a single solid strand of wire is more efficient in terms of its current-carrying capacity, having less resistance for a given current than a multi-strand wire of equivalent outside diameter, the likelihood of the wire breaking as a result of repeated bending (and therefore the difficulty in routing around tight corners in the engine compartment) is such that multi-strand wires are always used. Since the next convenient packaging arrangement after the single wire is seven (one inner surrounded by six others) followed by 19 (one inner, six intermediate surrounded by 12 more on the outside), most engine aftermarket harness wires will be configured in this last way.

Other than weight, flexibility or robustness, another factor in selecting the wire size is the resistance to the flow of current and hence the drop in potential difference across it. For short runs (less than 15 ft) a multi-strand copper wire with a cross-sectional area of about 0.8 mm2 - about 18 AWG (American Wire Gauge) - can take 6-10 A continuously from a 12 V source without overheating or causing an excessive drop in the voltage across it. At 0.5 mm2 (about 20 AWG) this drops to 4-6 A; at 0.2 mm2 (about 22 AWG) it falls to 2-3 A.

Since most sensor inputs and outputs from the ECU will be measured in milliamps rather than amps, it would be safe to say that the 0.2 mm2 wire would be around the lowest weight option. For power devices - injectors, fuel pump, ignition and 12 V supply - the larger wire with a greater cross-section might be best. In the end, however, the size you use will depend very much on the connectors adopted, and since many aftermarket systems use automotive OE-type connectors, the ultimate choice is therefore likely to be either 0.8 or 0.5 mm2. When other, smaller aerospace connectors are used, the potential to minimise the weight of the loom is much greater.

There are many factors to be considered when designing an engine wiring harness. Setting aside other issues such as insulation, screening and the type of sheathing used, optimising it all to produce a neat workmanlike solution is an art in itself and seldom appreciated by the wider motorsport fraternity.

Fig. 1 - A typical aftermarket wiring harness

Fig. 2 - Wire strand options

Written by John Coxon