Elastomer compatibility with ethanol in fuel

In recent years the Renewable Transport Fuels Obligation (RTFO) in Europe has caused much consternation to owners of older vehicles, including many vintage, classic and not-so-old race and rally machinery. Effectively requiring EU countries to introduce ethanol biofuel into gasoline at the rate of up to 5.75% by 2010, the push by the EU is now to increase this to 10% in the not too distant future and even further (20% and higher) thereafter. In a previous article I outlined some of the issues surrounding the incompatibility of various metals with the fuel, but now I want to expand the discussion to look at its incompatibility with many of the elastomers and sealants used on older vehicles.

Now, it has to be said that that the experience of many countries adopting higher rates of ethanol sooner has not apparently been as calamitous as feared. This could be because those countries don’t have as much of a history of running older vehicles as in the UK and US, but when it comes to the safety of our fuel systems and the seals used therein, it pays to be careful.

In 2008, the Minnesota Center for Automotive Research published a series of papers looking at the effect of E20 (20% ethanol in gasoline) on fuel system plastics and elastomers. The study was to compare the effects of E20 with those of E10 and non-oxygenated gasoline (that is, containing no ethanol) fuels by testing to Automotive Industry SAE and ASTMS standards.

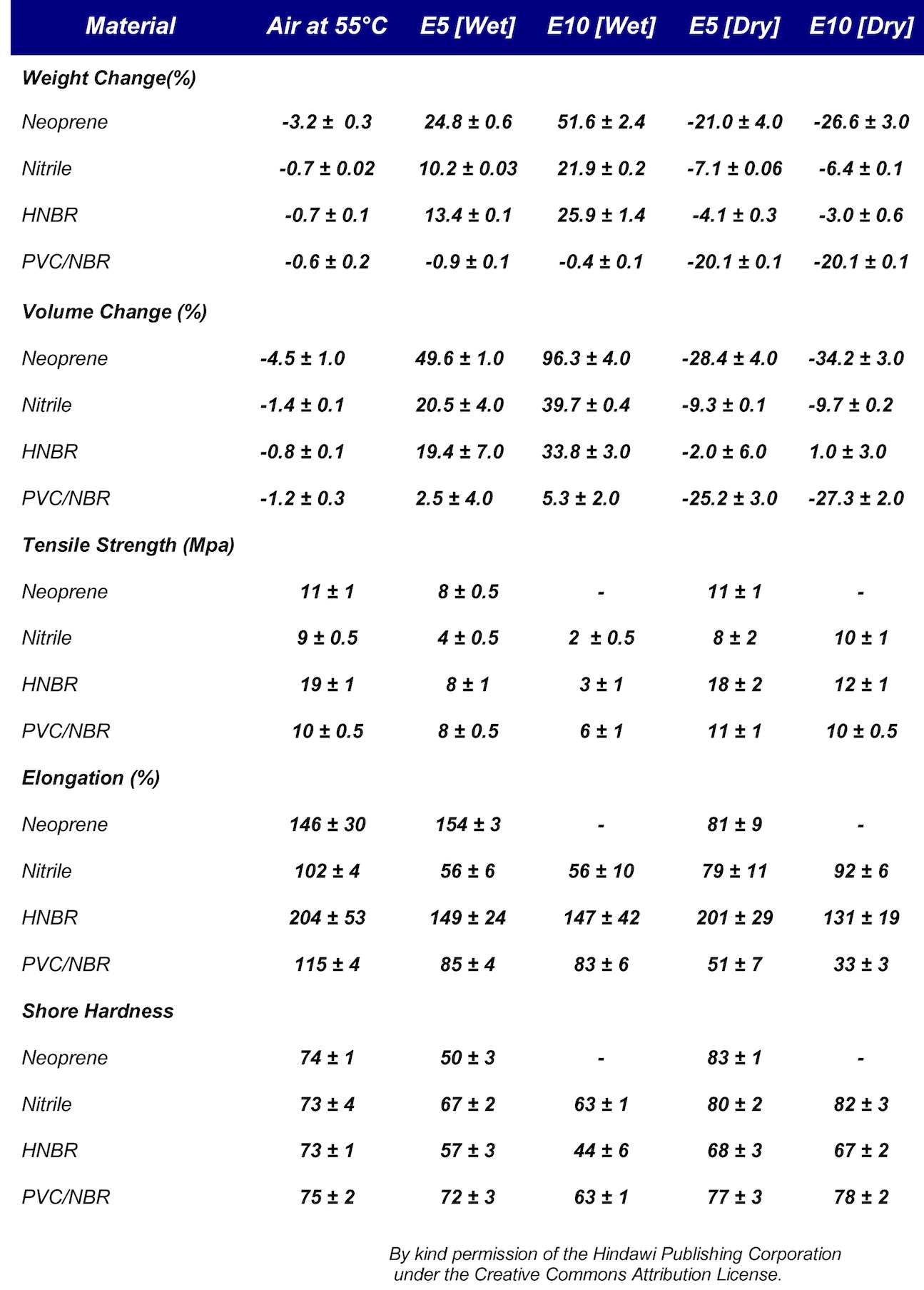

In the case of the elastomers, samples were prepared and immersed in the fuels at 55 C for 500 hours, after which changes to their physical properties of volume, weight, tensile strength, elongation at break and hardness were measured. The results of testing acrylic rubber, polychloroprene (Neoprene), nitrile rubber (NBR), nitrile/PVC and fluorelastomers showed that although there was a degree of swelling for all of them when the samples were immersed, there were no significant changes in hardness or tensile strength.

Apparently sponsored by the US Department of Agriculture, however, which was encouraging the growing of wheat corn for the production of ethanol, this report was not considered to be totally independent, so when the Indian government was considering a move from E5 to E10 the work was repeated. Testing four types of elastomer – Neoprene, NBR/PVC, hydrogenated nitrile butadiene rubber (HBNR) and nitrile rubber – representing those commonly found in their markets, and using fuels more typical of those found in India (19% olefin, 28% aromatic), the results were interpreted slightly differently.

Since the weight and volume of the Neoprene samples were far greater it was concluded that, compared to the E5 fuel, Neoprene was totally incompatible with that of the E10. For nitrile and HBNR specimens there was also a significant increase in weight and volume between E5 and E10, which at the same time was accompanied by a loss in hardness and tensile strength. HBNR and nitrile rubbers were therefore also considered to be incompatible with E10. On the other hand, PVC/NBR showed better overall resistance from E5 to E10.

So while in the wet state all the elastomers apart from PVC/NBR exhibited some significant degree of swelling in both E5 and E10 fuels, when dried they all showed signs of some level of leaching – all of which proves that with hundreds of different types of elastomers currently used in engines, many older designs could experience sealing failure with the advent of higher levels of ethanol in fuel.

Fig. 1 - Test results after immersion in the fuel

Fig. 1 - Test results after immersion in the fuel

Written by John Coxon