The airbox

For an engine to deliver its maximum performance it needs an adequate supply of cold, dense air. In a dynamometer test cell with good ventilation, engine air intake temperatures should not be an issue and are generally around that of the ambient air. When the engine is settled into the confined place of the engine bay of a race machine or nestling under the hood of a passenger car, however, the situation is most likely very different. In such instances cold, clean air may have to be ducted to the engine intake from either outside the vehicle or from a suitable position within the vehicle, and in such cases this is normally into an airbox.

The advantages of this are not just in supplying a denser charge to the engine. In directing the open intake of the ducting away from the outside of the vehicle, the inevitable roar of induction can be reduced or directed such that the external or drive-by noise will be below that of legislated levels. Like it or not, few racing circuits or motorsport venues these days allow unrestricted noise levels, and any method of reducing the pulsation so necessary further up the intake tract (but without affecting performance too much) has to be taken. Even the seemingly smallest of airboxes can be surprisingly effective at times, and pointing the entry away from the external boundary of the track can sometimes mean the difference between passing the inevitable noise test or not. A perfect example of this is in the world of karting, which mandates the use of an airbox - not, as you might think, to provide cold-ish air to the engine but to redirect/attenuate the high-frequency, eardrum-piercing noise of their high-speed two-stroke engines.

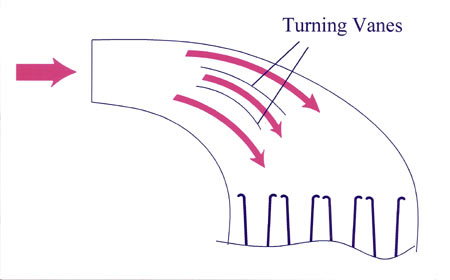

But not only can this airbox help to supply cold air to the engine, it can also be used to capture the forward motion of the vehicle and convert the (albeit small) velocity head thus generated into useful 'static' pressure energy. But in doing so the truly tricky task is to ensure that the air supplied is as evenly distributed as possible across all cylinders throughout the engine speed range and at all vehicle speeds. If an engine is installed in an east-west configuration - as in the case of, say, an ex-motorcycle engine in a single-seater racer - then if the intake tract is brought into the box centrally to the cylinders of a four-cylinder engine, the airflow will biased towards the centre two cylinders, with the outside pots being the losers. Baffles or turning vanes at the entrance to the box can be used to redress the situation, but a better solution may be to split the intake into two along the centre line of the car and introduce the split airstream centrally between cylinders 1 and 2, and 3 and 4.

When an engine is installed north-south the task is altogether more difficult. The air coming in from an overhead intake will invariably be biased towards the rearmost cylinders, and although baffles or turning vanes will be used to redistribute the flow, the complexity of the situation is often left to either trial and error or virtual analysis using CFD techniques.

As winter approaches, cold air might see the death of some of us mere humans but to the gasoline engine it is the elixir of life.

Fig. 1 - The cold air intake needs careful design

Written by John Coxon