Variable geometry manifolds

At a time when many if not most high-performance road vehicles have some kind of variable geometry intake manifold, it seems absurd to ban such systems for the latest breed of Formula One machines. Originally outlawed in the mid-2000s on the grounds of spiralling development costs, but rumoured to be reinstated again in 2015, this will add yet another layer of complexity to the modern Formula One powertrain.

Although rare back in 2005, variable geometry intake manifold systems for Formula One engines were relatively simple and generally fell into one of two formats. The first was a two-position device that moved in a straight line up and down inside the intake plenum to give two effectively differing lengths of intake tract. Comparatively simple in its concept, its limitations were always the point at which the switchover was to take place and the speed with which this would happen.

The second system was a development of the first, and consisted of a pair of concentric telescopic tubes running inside one another. In response to a speed signal the tubes either expanded or collapsed to give an infinitely variable length trumpet. Potentially more controllable since instantaneous switching wasn’t the issue, the downside here was that in spraying fuel down the intake ports (engines were port injected in those days), as the engine speed increased and the telescopic tubes collapsed then any fuel attached to the wall of the intake would be scraped off and be drawn into the engine, creating a richer fuel-air mixture than the one mapped; a momentary fall in power could result. With modern engine control systems this could be combatted to a certain extent in software but back then, according to reports, the effect on outright performance was noticeable.

Modern Formula One engines are of course directly injected, so the problem of stray fuel altering the carefully metered fuelling is now non-existent. Freed up from this need though, what might the variable geometry intake manifold of 2015 look like?

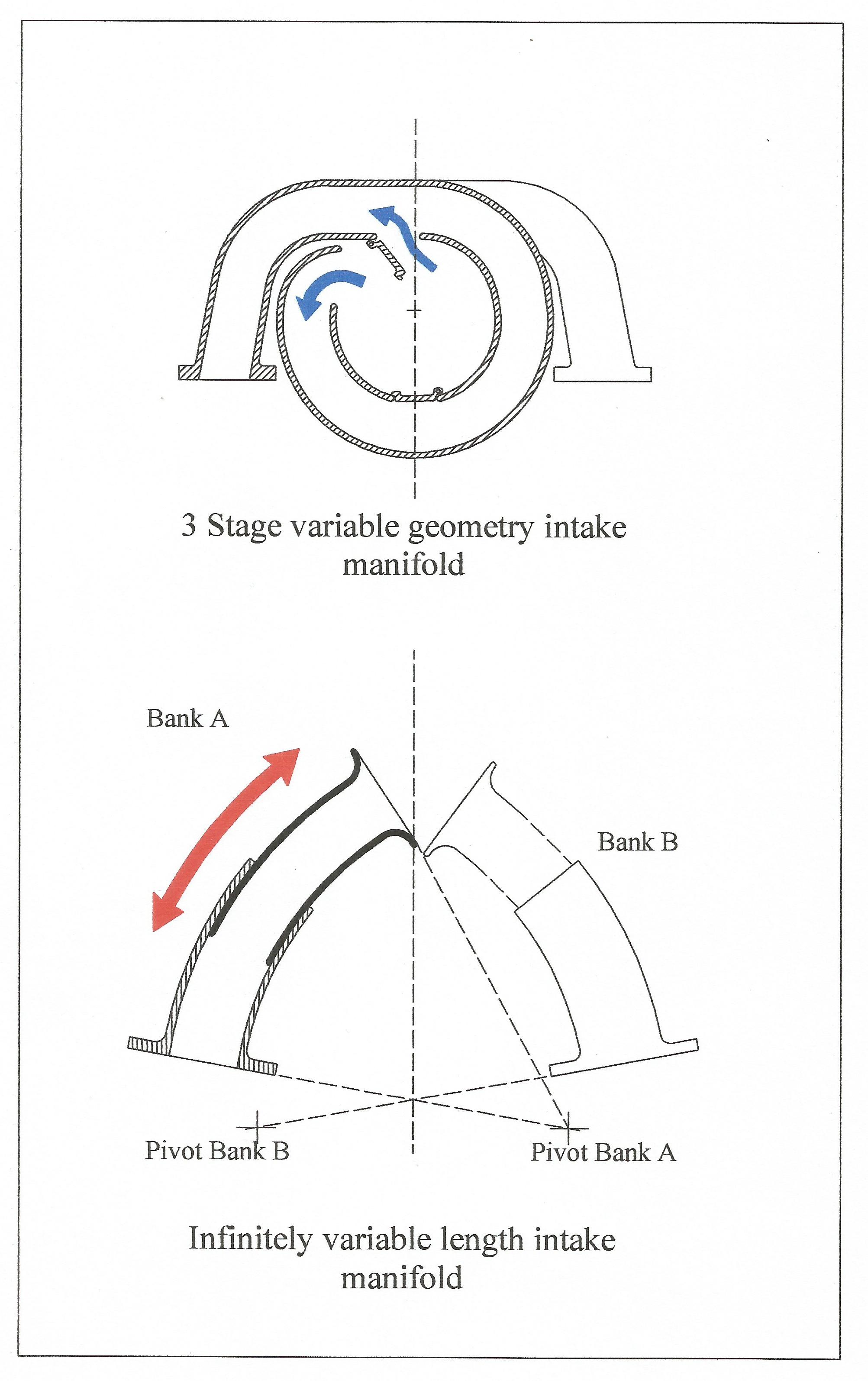

Of course we could go back to a development of the first system above from about ten years ago. This would work quite well but might increase the height of the engine installation to ensure that, as the intake runner length increased the proximity of the top of the airbox would not inadvertently restrict the air flow Another way might be to introduce a system of two or even three stages using an arrangement of flap valves inside a compact V6 intake manifold, similar to those used in a number of production vehicles from about 15 years or so ago. With an array of one or two sets of flap valves, two or three different intake runner lengths could be accommodated within the confines of the engine vee.

For my part, I thought I might want to examine a design based on the combination of the two – a simple continuous collapsible tube which in the shape of an arc could be moved by either electrical or hydraulic means. Not of much interest to the roadcar business perhaps, and therefore possibly not strictly roadcar-relevant as Formula One is supposed to be these days, but such a system could minimise the height of the airbox if this was indeed and considered an issue. It might be fanciful, and it might be difficult to make – and perhaps take a bit of development – but isn’t that what Formula One is all about?

The real question though is that with the availability of turbocharging and no restrictions on the level of manifold boost, in terms of outright performance is there any significant advantage to a variable intake system in place of simply more boost?

Fig. 1 - Ideas on variable intake manifolds

Fig. 1 - Ideas on variable intake manifolds

Written by John Coxon