Funny Car piston life

Mike Neff handles two jobs in the Funny Car category of NHRA Full Throttle Drag Racing - he is both the chief tuner and driver of the John Force Racing (JFR) Ford Mustang that currently tops the Funny Car points ranking and is the first car to qualify for the Countdown to the Championship play-off of six races, which starts after the Mac Tools US Nationals.

Mike Neff handles two jobs in the Funny Car category of NHRA Full Throttle Drag Racing - he is both the chief tuner and driver of the John Force Racing (JFR) Ford Mustang that currently tops the Funny Car points ranking and is the first car to qualify for the Countdown to the Championship play-off of six races, which starts after the Mac Tools US Nationals.

Neff handles the dual role easily, as he performed tuning duties for 2005 champion Gary Scelzi in the category, and in 2008-9 - his first year of competition - he was the fourth driver for JFR, earning the Auto Club Road to the Future (rookie of the year) honours in.

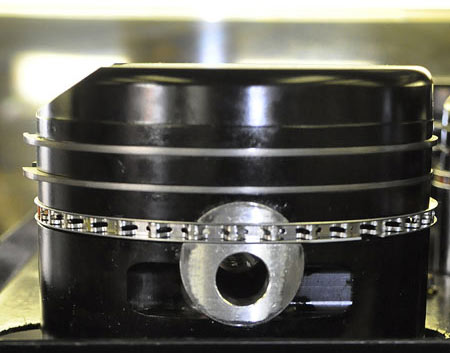

With direct control over all aspects of his 8000 hp racecar, Neff is able to specify the precise ingredients he needs to get his car down the 1000 ft dragstrip without injury or delay. He specifies Venolia pistons for his Funny Car - as he does for the entire JFR team - using a three-ring (compression, oil and oil expander) aluminium piston, telling Venolia's Tom Prock what he wants. "We get the most wear around the top ring, but usually they last pretty good and don't wear too much," Neff says.

Service life can be anywhere from one to six runs, depending on "how hard we step on it" during a run, says Neff. Compression for the Funny Car engine is only about 6.8:1, "but we might go higher, depending on the atmospheric conditions" he adds, and certainly higher at the Mile High Nationals outside Denver. "Here in Denver you've got to raise it up pretty good, but when you're at sea level you lower the compression, so that number will always vary, but the same amount of pressure is always on the engine," says Neff.

In Denver, Neff says he will also fit a gasket that is anywhere from 25-35 thousandths of an inch thinner to cope with the lower air density that comes from being a mile above sea level; there is not necessarily more pressure on the pistons at altitude. "You still have the same amount of pressure on the engine - that's what you're dealing with by raising and lowering the compression," he says. "The pressure pretty much remains the same.

"What makes it tough at Denver is the engine idles a lot different; you get a hot piston or something and the engine will start working more on one piston than the others," Neff explains. "Generally, if everything gels and you set it up just right, it shouldn't be any worse than at sea level. Idle circuitry is different up here. You tune it up and change the air-fuel mixture; it's just a little different and you have to adjust to it."

At Denver, piston service life is higher because the altitude is harder on parts. "You have to make big changes and it's hard to get it all ironed out in the short amount of time we're here," Neff says. "You're going to hurt more parts up here than say in Norwalk, Ohio," which is much closer to sea level.

While Neff says he might see higher piston wear on the top compression ring, skirt wear is not bad. "We kill the skirt sometimes but not on a regular basis. It's hard to say if it's worse in Denver than anywhere else. You take your best educated guess on a starting point and look at it from there."

JFR hasn't changed its piston spec since going from 1320 to 1000 ft a couple of years ago. "It's really no different. It's just another half-a-second and you're trying to run as quick as you could everywhere else. The fact is, you're just shutting off a little earlier and that doesn't require you to change the engine.

"A thousand feet lengthens our piston life a little bit because you're not on the throttle as long, so you're less likely to hurt anything. It's at the end of the track that you're most likely to hurt a piston. The longer you're on the throttle, the more damage you're going to do, so it definitely helps the engine, parts-wise, going to 1000 ft."

Fig. 1 - Mike Neff specifies the piston he wishes to use at every NHRA event (Photo: Anne Proffit)

Written by Anne Proffit