Piston pins, surface treatments and coatings

As discussed in previous RET-Monitor articles and in the pages of Race Engine Technology magazine, reducing the mass of a piston assembly is especially valuable because it then allows design engineers to reduce mass of all of the downstream components. The piston pin is a significant mass, and any reduction here allows weight to be removed from an optimised con rod and crankshaft. The temptation is to make piston pins smaller in every dimension – that is, outside diameter, inside diameter and length – but doing so reduces the piston pin’s stiffness, and the designer needs to consider the consequences of this in terms of stress and deflection.

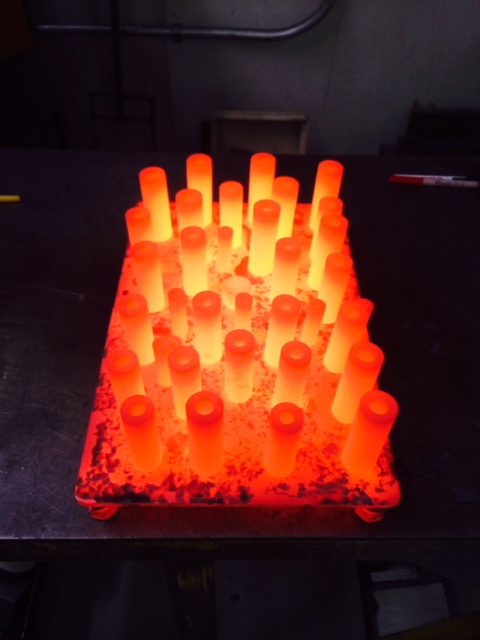

The role of surface treatments and coatings is important here: if selected correctly, they can significantly increase the durability of the component. If we look at the common example of a steel piston pin, there are a lot of possible surface treatments and coatings. However, we find that racing pins are very often made from a nitriding steel, or other types of steel that respond well to nitriding even if they weren’t ‘designed’ for this purpose.

The nitriding treatment both hardens the surface and puts it into a state of residual compressive stress. The hardening of the surface is an important factor in making the surface resistant to damage, and the compressive residual stress means the pin is much more durable – its fatigue resistance is increased markedly for any given level of service load. The resistance to surface damage is an important part of this fatigue resistance too: as the surface is difficult to damage, there is little risk of a significant stress concentration forming during the piston’s working life.

Coatings are an important consideration as well. As with nitriding, hard low-friction coatings also increase wear resistance and also reduce any tendency for the component to seize in either the con rod or the piston. The most common type of coatings we find on racing piston pins are the diamond-like carbon (DLC) group. If DLC is not properly ‘supported’ by the substrate though, there is a risk that small particles of what is a very hard, sharp and abrasive coating could be introduced into the contact between pin and piston or between pin and rod bore, where they would be likely to cause significant damage.

The effect of strengthening the surface of the component by surface hardening is an effective way to improve the durability of coatings. The hardening process, if properly specified and carried out, prevents the pin surface from yielding. While DLC coatings are very good, however, they are not known for their ability to conform if the substrate deforms plastically.

Nitrided piston pins were very popular before DLC-coated pins started to become commonly used, perhaps 15 years ago, although their superiority over non-hardened pins had been obvious for a long time. With the advent of piston pins with hard coatings that could potentially cause damage if they were to fail, the role of the nitriding is therefore more important than ever.

Written by Wayne Ward