Pushing For Victory

Mark Smith’s PME Engines of Mooresville, North Carolina powers the NASCAR Camping World Truck Series (CWTS) entries of Ron Hornaday Jr and Matt Crafton, currently first and second in points as the campaign hits its home stretch.

Mark Smith’s PME Engines of Mooresville, North Carolina powers the NASCAR Camping World Truck Series (CWTS) entries of Ron Hornaday Jr and Matt Crafton, currently first and second in points as the campaign hits its home stretch.

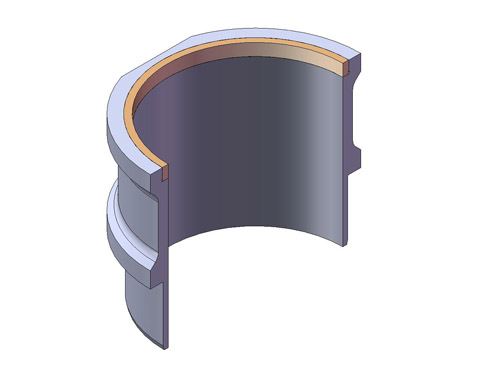

To keep things consistent, there’s not much out of the ordinary that he’s ready to do with his Bill Miller and Mahle pistons at this point in the game. “We do a lot of testing with different moly coatings on the rings and ring lands,” he told me at Chicagoland Speedway the final weekend of August. “It’s all about how the ring seals – some of them are not as compatible with the aluminium as others, so sometimes you have to coat them to make them survive.”

Since NASCAR does not allow exotic materials such as beryllium or titanium for the CWTS pistons, the sanction looks for a parity weight rule, requiring pistons to weigh a minimum of 400 grams. “Depending on your rpm limits and what your power level is, that’s how you decide how aggressive you want to go with the piston.”

There’s a wide variety of moly coatings available to Smith and to him, “It seems like every week somebody comes up with a new coating for us to try.” Of course, when you change the piston coating, it’s easy to cause imbalance elsewhere in the driveline. “It’s never a ‘freebie.’ If you do something to the piston it usually affects something else. There is different growth in different areas so you have to be careful,” particularly with ceramic coatings.

“You change different designs on the pistons because of where the heat is. We try to test as much as we can with significant time on the dyno and then we’ll take it to a short track, somewhere with throttle changes where you’re on and off the throttle quite a bit to test the parameters.” NASCAR has scotched testing at series circuits.

In the CWTS, the trucks run pretty much ‘flat’ at a place like Chicagoland Speedway, a 1.5-mile oval. “They are wide open all the time and it’s pretty tough on the pistons, so short track testing doesn’t bear on Chicagoland,” Smith said. “Sooner or later you have to put it in the vehicle,” so he finds other teams to test new pistons for him. “I hate to put something brand new into Ron’s or Matt’s trucks because they are in the points chase. You can’t take a chance on that stuff.”

He’s not the only one testing his pistons in this manner. “Everybody else is testing like this, too. You just have to be smart where you change things. When you test at a short track, you don’t get the same things you get on a mile and a half like this. Tracks like this are pretty significant for a truck, because they do run so wide open.”

NASCAR mandates fixed gear ratios for the trucks that keep them around 8000-8200 rpm. “That’s about all we’ve got, but we used to run about 9500 so we’ve got less friction now because of the revolutions. All those things come into play with our pistons but the big thing is making them live at a track like this because they are running wide open all the time.”

Written by Anne Proffit.