Revolutions in Rings

For as long as I can remember, it has been considered best practice to position the ring gaps equidistant around the piston. The theory is that in doing so, gas leakage will be minimised so that it stays within the confines of the combustion chamber, expands and generates more shaft power. For some reason - and I no longer understand why - it just made common sense and was never really challenged.

For as long as I can remember, it has been considered best practice to position the ring gaps equidistant around the piston. The theory is that in doing so, gas leakage will be minimised so that it stays within the confines of the combustion chamber, expands and generates more shaft power. For some reason - and I no longer understand why - it just made common sense and was never really challenged.

At the risk of stating the obvious, gaps in piston rings are a physical necessity to aid assembly and assist with the inevitable expansion of bore and piston. When in place, therefore, a gap of 0.003-0.005 in per inch of bore diameter is generally recommended.

In two-strokes it is common practice to peg the ring to prevent it from rotating, since not to do so would risk the gap edge digging in and scoring the bore as it crosses the exhaust port. In preventing it from rotating though, the risk is that both ring and bore will wear non-uniformly and compromise durability. In four strokes, however, the reverse is true and the rings are not restrained, other than by the groove and liner surface.

These days though, and now somewhat enlightened, I prefer to subscribe to the school of thought that if something can move, it will. So if a nut can fall down inside the tappet chamber when assembling an engine, it will. And of course, if God had intended piston rings not to rotate he would have made sure they physically couldn't in the first place.

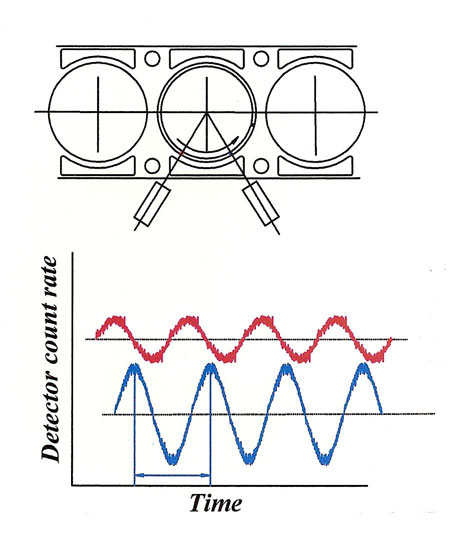

The point was brought home to me by a piece of research carried out a surprisingly long time ago now, which involved making a very small section of a ring radioactive and then looking at the gamma radiation given off using a sodium iodide scintillation tube placed next to the cylinder block. During testing, and despite the noisiness of the signal generated, a sinusoidal output could be clearly seen as the ring (presumably) rotated and moved away from and then back towards the detector.

Using more advanced, statistical analysis merely enhanced this characteristic. The frequency of the signal was highly variable but depended on the engine speed and load, with a maximum correlating roughly to engine speed - for every 1000 rpm by the engine, the ring rotated by a maximum of roughly one.

In later work, it was also suggested that not only could the rate of rotation be measured but its direction as well. The theory went that by dosing another portion of the ring with another radionuclide - different from the first and having a gamma-ray signal differentiated from it - and using a second scintillation tube, the direction of rotation could be deduced.

That rings rotate is no longer disputed. In which direction and why, however, is the subject of much debate. Maybe it's all to do with the cross-hatching of the hone, or it's a much more complex issue than we can ever hope to resolve. Either way, there seems little point now in staggering the rings' gaps - but despite our new-found knowledge, we'll still do it.

Fig. 1 - Measuring ring velocity and direction

Written by John Coxon