Steel piston tech

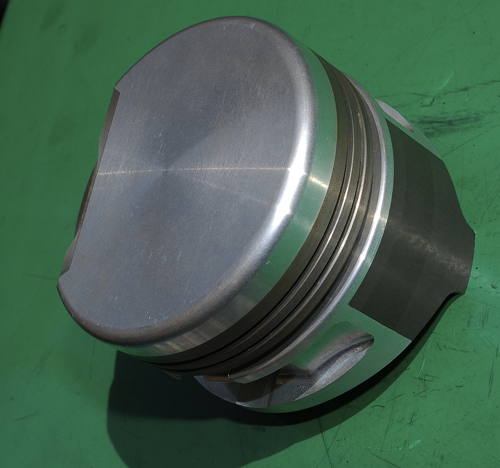

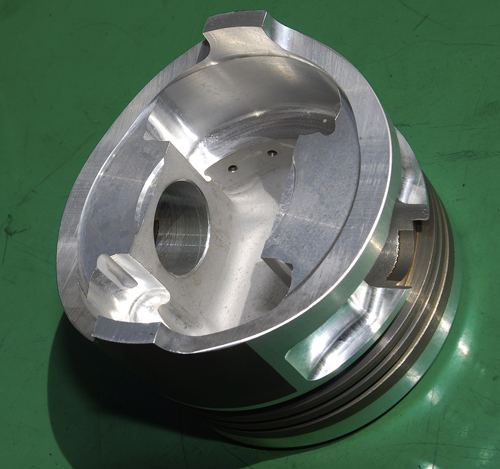

Ever the innovator, NHRA Funny Car crew chief Austin Coil of John Force Racing is currently investigating the use of JFR-produced forged steel ring land inserts on the Venolia pistons used on 14-time Funny Car John Force’s Ford Mustang. “It is a lot like units that the diesel pistons have and the approach was used very successfully in the turbocharged Honda Formula One cars, back in Ayrton Senna’s day,” Coil told us. “But since we can’t afford a million dollars for pistons, we have to find some way of doing it other than the electron beam routing they used.”

Ever the innovator, NHRA Funny Car crew chief Austin Coil of John Force Racing is currently investigating the use of JFR-produced forged steel ring land inserts on the Venolia pistons used on 14-time Funny Car John Force’s Ford Mustang. “It is a lot like units that the diesel pistons have and the approach was used very successfully in the turbocharged Honda Formula One cars, back in Ayrton Senna’s day,” Coil told us. “But since we can’t afford a million dollars for pistons, we have to find some way of doing it other than the electron beam routing they used.”

There are many issues to work out with the steel insert and Coil’s efforts stalled by the fact that NHRA limits testing during the 2009 season to only four days per car. “We have rules against testing in-season, so this project is on the back-burner until next winter when we can test again,” he said. “The reason we are looking into this is because pistons get pretty hot. Aluminum gets weak really quickly and when it gets hot, the ring lands bend and/or they crack. That causes us to replace an awful lot of pistons,” Coil said. “And frequently, that is a limiting factor on the tune-up. So, if the piston were just a little bit more rugged, you wouldn’t bend the ring lands and you might be able to run the same distance – let’s say 10 or 20 runs instead of just one or two.”

To Austin Coil’s mind, the benefits would far outweigh the initial extra development cost and the added weight of a steel insert into ring lands. “This could be a safety benefit and, eventually, it would be a cost savings. It might even be a little bit of a performance advantage too.”

There is but one such piston in existence. “We made the piston and supplied the process for making the steel ring insert fit,” advised Tom Prock of Venolia. “The beauty of it is that this is a billet piece of aluminum, forged to an 800-degree temperature and cylinder head temps exceed that. It might just work,” he said.

“The first product is a little too heavy and it is only coated in some areas. I intended to have the aluminum parts coated so they won’t hurt the cylinder walls,” Coil said. “We don’t know what the future will bring, but it certainly works in diesels and it certainly worked for Honda back in the Senna days, in the 1980s when Honda first came into Formula One with McLaren.”

Coil’s Venolia prototype is about 200 grams heavier than the race-ready products JFR uses from Tom Prock at Venolia. “We think we can get it down another 100 grams. It is probably doable,” Coil said. Trying to run the piston “to see what it might tell us, the problem is that this piston is so much heavier than the other ones that I wouldn’t want to run one of them; you’d have to make a whole set.”

Coil spoke with the engineers who made the Honda pistons for their Formula One project. “When I started talking about doing it, they said that might be really expensive. In Formula One there is no budget limit, if a piston costs a million dollars, it costs a million dollars. And we don’t have a million-dollar budget for pistons,” Coil laughed.

Written by Anne Proffit.