The gapless ring

It may sound obvious, but to assemble a piston ring into its grooves in a traditional two- or three-ring piston will require the ring to be split at some stage during manufacture. Placed on some form of mandrel and heat treated thereafter to an out-of-round set, once placed onto the piston and assembled in the cylinder, the theory is that it should exert a more or less constant pressure all the way around the bore.

It may sound obvious, but to assemble a piston ring into its grooves in a traditional two- or three-ring piston will require the ring to be split at some stage during manufacture. Placed on some form of mandrel and heat treated thereafter to an out-of-round set, once placed onto the piston and assembled in the cylinder, the theory is that it should exert a more or less constant pressure all the way around the bore.

Simple and yet highly effective, there are however two issues created by the inevitable gap in the rings that result. The first is the uneven wear that tends to take place at the edges of the ring next to the gap, while the second is the gap itself.

Examine any well-used compression ring and, close to the edges to the gap, you may see that the witness marks left by the ring moving up and down the bore tend to splay out just before you reach the gap. It's not much of an issue in itself, especially if you're talking about competition engines when rings are regularly replaced, but it is an indication perhaps that the rings twist somewhat differently near the gaps, and may or may not indicate uneven loading. The gap, however, is another issue.

At first thought it might be desirable to have little or preferably no gap at all, but as the piston, the rings and the cylinder bore expand and contract due to changes in temperature and/or mechanical load, these components will expand and contract at different rates. And while a zero gap might minimise combustion gas blow-by, should the two ends 'butt' together then the resulting geometric effect would be to transfer any further relative thermal expansion into additional radial load on the bore. Factor in its associated friction as well and, at worst, the heat generated would be rapidly followed by breakdown of the cylinder lubrication and catastrophic seizure.

Clearly, therefore, this 'gap' is more critical than at first thought, and when set to the supplier's recommended figures it should minimise the chance of seizure.

In service, however, this gap can allow combustion gas to bridge the ring, which not only costs engine performance but creates an instability in the zone between first and second compression rings where combustion gas is essentially 'trapped'. One enterprising company, however, has come up with a novel and unique design.

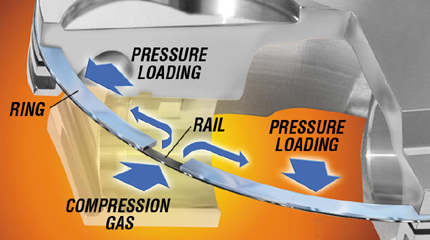

Protected by a design patent, the gapless ring system consists of an upper ring of such a cross-section that another, narrower lower unit can be assembled coaxially alongside it. Each ring has a traditional ring end gap associated with it but when assembled into the ring groove, so long as the two gaps don't align, no combustion gas can escape through this route. During engine build the gaps in each are set individually and are positioned about 15º apart around the piston ring groove.

Knowing that piston rings tend to rotate, I would have thought differently, but apparently during use the two rings rotate more or less as though they are clamped together to form an assembly. These gaps therefore hardly ever line up. However, even in the worst case, when excessive detonation in say a turbocharged engine causes them to rotate independently, according to the manufacturer the situation can be no worse than a normal single-gap ring. Used in many applications in all the major racing formula with a high degree of success, this design can be used equally successfully in first or second compression ring positions.

Although the manufacturer doesn't say so, these rings may also give a more even loading around the cylinder bore.

Fig. 1 - The gapless ring

Written by John Coxon