Methods of closing hollow valves

In the recent Race Engine Technology article on valves, there was some discussion of the merits of hollow valves, and indeed the subject has been covered by Anne Proffit and I in these Monitor articles in the past.

In the recent Race Engine Technology article on valves, there was some discussion of the merits of hollow valves, and indeed the subject has been covered by Anne Proffit and I in these Monitor articles in the past.

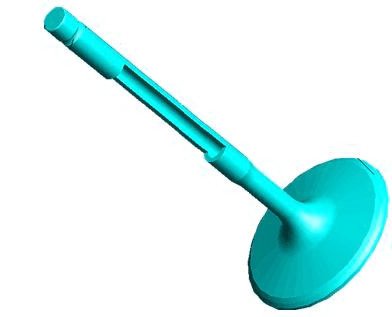

We should briefly restate here the reasons for hollow valves. The first and more obvious reason is mass reduction in cases where a reduction in stem axial stiffness does not compromise the proper action of the valve or present problems through lack of bending stiffness. The second reason is to allow the use of an internal coolant, which is commonly metallic sodium. This has been a common measure for decades for some non-racing applications and its use is widespread in racing. Indeed, valves where the hollow stem is joined to a hollow head can be used where the rules allow.

One factor that every kind of hollow valve has in common is the requirement for the hollow stems to be closed. Naturally this is more critical in the case of internally cooled valves, where lack of sealing could allow the escape or oxidation of the liquid coolant, rendering the cooling effect less effective.

There are various methods for closing hollow valve stems. One of the simplest is to insert a plug, and is suited to hollow stems drilled from either end - clearly, it is possible to drill the hollow stem from the tip end or the head end. An interference-fit plug is a simple way to produce the desired sealing effect and, where the same material is used for the plug as the valve, the required interference is very small; it is also possible to weld a plug or plate to close the hole. Laser welding or electron-beam welding would be suitable methods for this operation, as both produce clean, consistent and very accurate welds.

Swaging is one method which is totally mechanical and requires no extra parts to be attached to the main body of the valve, either through welding or the use of an interference fit.

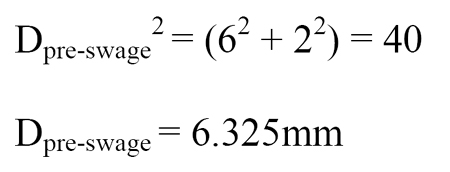

Swaging is a process of radial deformation, and basically the hole is squeezed closed. The method is commonly used in a number of applications, both in motorsport and general automotive use. Hollow driveshafts are often swaged to produce the 'necking' down from the large diameter of the hollow shaft to the splined ends. Clearly, before the swaging operation, there needs to be sufficient cross-sectional area to produce a solid stem. If we take the example of a stem with a 2 mm internal drilling and a 6 mm finished stem diameter, the pre-swaging diameter will need to be 6.235 mm, as shown in this calculation:

After the swaging operation, there will obviously need to be some machining, so the pre-swaging outside diameter will need to be somewhat greater than this calculated diameter. A side-effect of swaging is that, with it being a process of mechanical deformation, the material thus deformed will be work hardened.

Fig. 1 - Hollow valves are commonly used in racing but require a reliable way to close the drilling, especially where sodium cooling is used

Written by Wayne Ward