CFD: why Formula One is creating its own (and less useful) branch of the science

Formula One is often held up as an innovator, a creator of new technology and inventions. It is debatable to what extent this is true, but for CFD technology there have been direct benefits driven by Formula One over the past 10-15 years. This ‘sharpening’ of CFD tools – as in better accuracy, ease of use, speed and so on – has helped almost all other CFD users, from the more mainstream automotive engineers to Olympic cyclists, to do more. But there is a real danger that the money Formula One spends on pushing CFD tools forwards in a useful direction is grinding to a halt – in fact it’s starting to grind on a different set of CFD tools that are far less useful to the wider automotive world. Why? Because Formula One works to beat rules, and FOTA rules around CFD computing power are driving Formula One to do odd things with CFD that other users of the technology wouldn’t find useful.

If we go back to the late 1990s then CFD was starting to be capable of full car analysis, with models that looked pretty complete but in fact weren’t really resolving the general external aerodynamics accurately. The models were around one-hundredth of the size they are these days and would take weeks to build and days to calculate the airflow around it. But in the background was always Moore’s Law, which states that the number of transistors on a chip roughly doubles every two years. In other words, computers become exponentially quicker. So CFD has been tracking the digital revolution and the power/price of the home PC.

Hardware aside, these days there are a few other areas where progress must be recognised. The software tools for building the CFD models have improved massively. Ten to 15 years ago, meshes had to be almost hand-stitched together, but now we can drive CFD directly from CAD in some cases where CFD runs are built, configured, computed, post-processed and reported automatically from a “go CFD” button in CAD. The tricky bit will always be figuring out what the results all mean and what to do next!

The other change is that open source CFD tools have arrived. We now have a choice between commercial codes and open source alternatives. This means two things: we can reduce the cost of doing CFD, and we can take the lid off the CFD code and poke around, change things and make it our own special version. Remember that commercial codes are closed; you can request modifications but you can’t get the source code and play around with it. All in all, great progress for the power, cost and ease of use for CFD over the past 15 years, and the gradient of progress is still there pinned to Mr Moore’s coat tails.

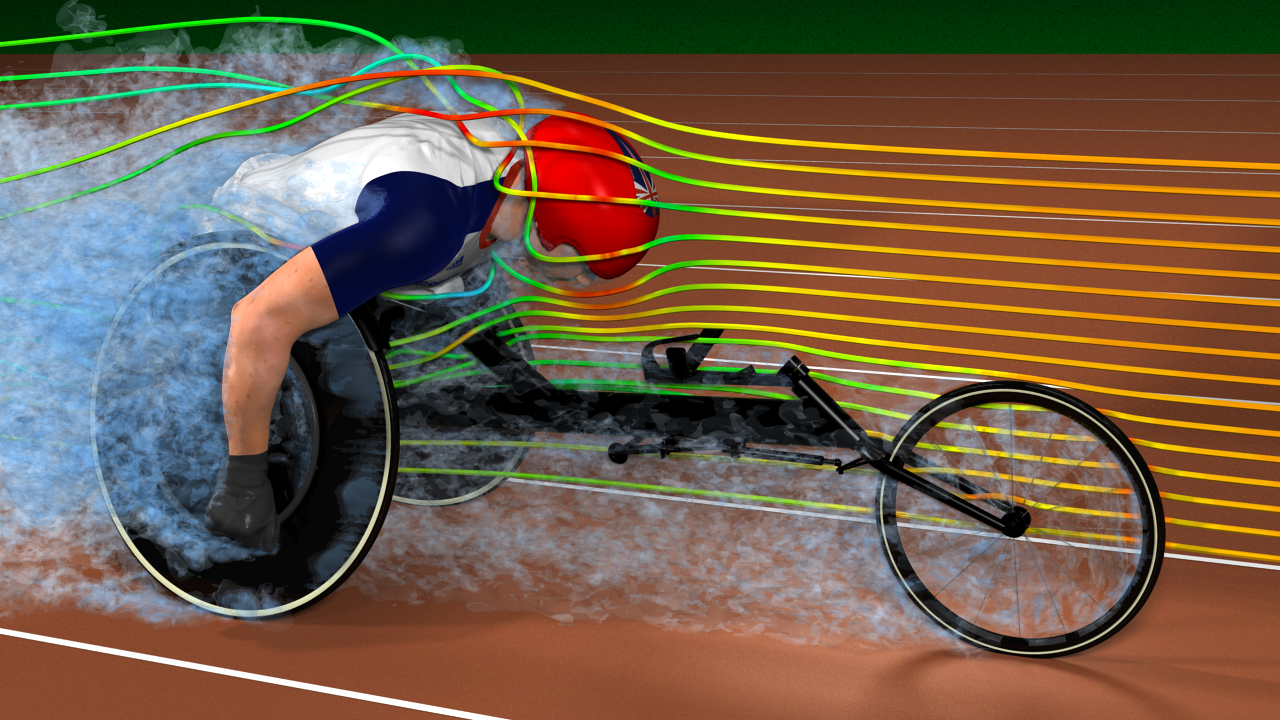

The world outside of Formula One is using CFD to tackle bigger and more complex problems. Roadcar companies are using CFD to solve unsteady flows rather than the time-averaged flow solutions that most Formula One teams still bank on. This means they can look at the unsteady wake and turbulence around a vehicle, giving them greater insight and a much more accurate tool to measure drag, noise, cooling, soiling of the car by dirt particles and aero stability.

Optimisation has become a widespread tool for many CFD users too. This is a process where the shape or design is parameterised, and CFD plus some maths works to morph the shape automatically to maximise a goal. Optimisation needs lots of computing power, and these days it is achievable even with complex full-car models.

Most Formula One teams, on the other hand, are working to a cap on the use of wind tunnels and CFD, either through previous FOTA agreements or in the future with incoming FIA regulations. There is a sliding scale between wind-on hours and CFD computing power, where a team can choose a balance between CFD and tunnel use, then work to that budget.

Most teams go for a sensible balance, with probably around 20 ‘units’ – teraflops of theoretical peak computing power – of CFD. The definition of a teraflop is a trillion (one followed by 12 zeros) floating-point operations per second. That sounds simple enough, but it’s the “theoretical peak” phrase where it all goes fuzzy. In theory, a current Intel 3.4 GHz six-core CPU can carry out six of these floating-point calculations per cycle, 3.4 GHz means 3,400,000,000 cycles per second, and there are six cores, so this chip is capable of 122.4 gigaflops, or 0.1224 teraflops.

With a budget of 20 teraflops, a Formula One team would max out at 163 of these CPUs, (or 980 cores) – not many really. But the real twist is how close a CPU can perform compared to its theoretical peak, and this is where some of the games start. So if one chip manufacturer produces a chip tweaked for Formula One that loses 25% of its theoretical power, but in reality for CFD calculations it loses only 5%, then it becomes a must-have for the teams. Just like working around rules for blown diffusers, the teams can find ways to stay within the 20 teraflop budget but still get more real computing power. This drives them to buy very specific hardware, often discarding perfectly good hardware at the same time. So while the rest of the CFD world is using the current quickest, best-value hardware, the Formula One teams using capped computing power are doing something else, and it’s not saving them money.

Another consequence of the computing power cap is that Formula One ‘can’t afford’ to follow the rest of the CFD world in doing real transient simulations. It is stuck largely with the teraflop-friendly steady-state science that for most vehicle aero research is becoming old school. Also, optimisation is becoming a no-go for Formula One, as it burns more computing budget than teams can afford to spare. It is steering them back to guys drawing parts and running them manually, rather than letting the computer take the strain. Formula One CFD solvers are being tweaked for efficiency, previous runs are being scoured for useful info, while new ways not to use computing power but solve more CFD are being sought at some cost. All the while, the rest of the world is asking the opposite question: “What can we do next with all this computing power?”

So what’s the real answer to budget-capping CFD? It isn’t simple; Formula One teams could do proper benchmarks of their hardware using standard CFD codes and models rather than relying on ‘theory’. In the end though there will be ways to tweak the benchmarks and work around any new rules. Perhaps the teams could all be allocated computing power from a central computing ‘cloud’ and be asked to make the most of it.

None of this is ideal, but there has to be a sensible solution somewhere that gets Formula One back on Moore’s law and using or evolving tools that the rest of the world would want. One solution could be financial budget caps that would drive the teams to seek productivity per £/€ spent on solutions, thus developing tools and processes that will have more appeal outside Formula One.

Fig. 1 - Unsteady CFD simulation and shape optimisation techniques were used to make gains for wheelchair and track cycling in 2012 (Courtesy of UKSport and TotalSim)

Written by Rob Lewis