Clearance matters

In theory at least, an engine bearing – be it big-end or crankshaft main – should be one of the simplest components to lubricate. Separated by a thin film of oil forced into a gap under pressure, when running at a constant rotational speed, the resulting ‘wedge’ of fluid forces the components apart, disengaging both shell and journal asperities. Since there is no contact between bearing and journal, no wear can take place and the power loss in the system is down to that generated only by the friction between the layers in the lubricant.

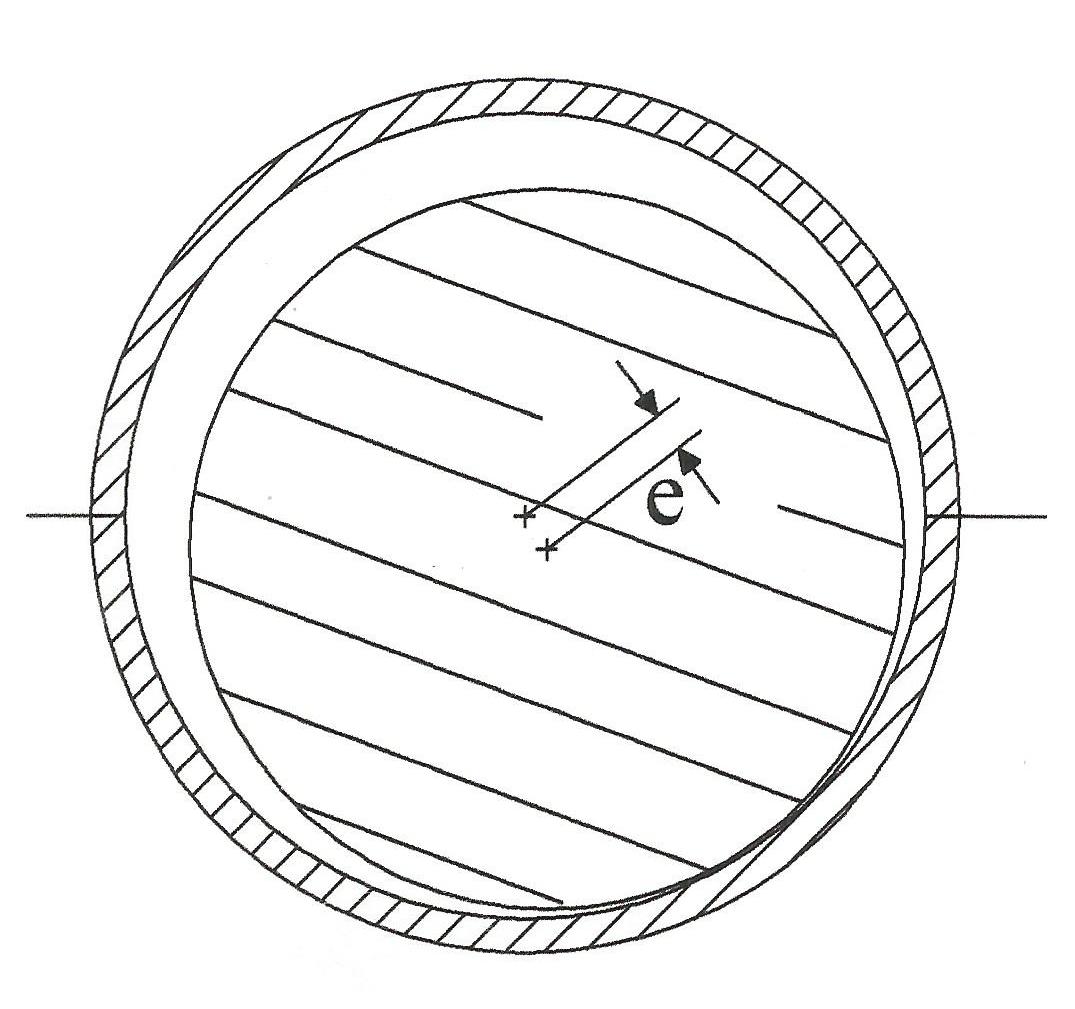

With oil film thickness measured in microns (0.001 mm) it is therefore critical to the performance of any such bearing to ensure that the dimensions, overall shape, surface quality and cleanliness are held within tight limits. Thus in designing a bearing, the critical parameter is that of the clearance between journal and shell, which is sometimes referred to as the ‘eccentricity’ of the bearing.

The function of the oil in any bearing design, however, is not purely to lubricate; another major aspect of all engine lubricants as applied to bearings is to remove any heat generated. So if a bearing appears to be adequately lubricated but the heat generated through the friction within the oil film is not dissipated, the bearing will eventually overheat and fail. While it is imperative to have sufficient viscosity in the fluid to support the loads generated, too much viscosity will reduce the flow of the oil and possibly also the rate of heat removal. If this rate of removal is insufficient, the bearing may become damaged and eventually fail.

Thus, if a particular engine was designed to run on an SAE 30 grade oil, for example, then using an SAE 60 oil for competition purposes might not produce the results intended. The increased viscosity might be able to support the increased loading, but the reduced flow rate through the bearings could introduce other issues. In reality, competition engines, through their widespread use of wide-open throttle settings and heavy rates of fuel enrichment to develop maximum power, will load often excessive quantities of unburned fuel into the lubricant, reducing its viscosity. At the same time, competition bearings may have greater clearances to allow for higher oil flows, so oil with a higher viscosity when diluted with fuel may be within the design limits of the bearings.

If you like, the oil clearance in the bearing will have an optimum value, taking into account the combination of design parameters associated with the actual lubricant in the sump rather than what it was originally filled with. Greater bearing clearances will cause an increase in the oil flow and give lower oil and bearing temperatures. But at the same time these clearances will give a less uniform pressure distribution within the bearing as well as higher peak pressures, and higher peak pressures can lead to increased loads and consequently reduced fatigue life. At higher pressures, the minimum oil film thickness resulting could also be lower, producing asperity (metal-to-metal) contact between journal and bearing shell, creating increased wear.

While outwardly straightforward, designing and developing ‘simple’ crankshaft and big-end bearings is a lot more complex than you might think.

Fig. 1 - Bearing eccentricity

Fig. 1 - Bearing eccentricity

Written by John Coxon