Diesel fuel

Regular readers will have realised by now that I am not a great fan of diesel-fuelled racers. Any reciprocating engine that relies on the temperature of the compressed intake air to be greater than that of the flash point of the fuel has no right to be positioned anywhere near the finely honed chassis of a racing machine, except in the vehicle designated to lug it and the rest of the team from circuit to circuit. This is a personal opinion, you understand, and while gasoline engines should be all about raw power the compression ignition cycle of the diesel unit is surely all about efficiency.

Regular readers will have realised by now that I am not a great fan of diesel-fuelled racers. Any reciprocating engine that relies on the temperature of the compressed intake air to be greater than that of the flash point of the fuel has no right to be positioned anywhere near the finely honed chassis of a racing machine, except in the vehicle designated to lug it and the rest of the team from circuit to circuit. This is a personal opinion, you understand, and while gasoline engines should be all about raw power the compression ignition cycle of the diesel unit is surely all about efficiency.

This is not to say, of course, that the diesel cycle cannot be made to produce stonking amounts of power. Simply up the boost pressure (for it must have a turbo or supercharger), tip in large amounts of fuel and watch the torque increase up to the limit where a plume of black smoke billows from the exhaust! The powers produced can be prodigious but a diesel engine is essentially a lean-burn machine that is better working in defence of our dwindling oil reserves hauling all manner of goods through the extreme cold of an Alaskan winter as well as the heat of a Nevadan summer. It is little wonder therefore that diesel fuel specifications are dominated by low-temperature characteristics such as 'cloud point', 'pour point' and something that formulators refer to as the 'cold filter plugging point' when wax solidifies out of the solution. These surely have little relevance to the demands of motorsport.

However, combustion in a diesel engine is altogether different from that of our traditional racing machine, the spark ignition engine, and this is reflected in the fuel used and how it is characterised. In our spark ignition unit the fuel-air mixture enters the chamber, and the stoichiometric homogenous charge ignited by the spark plug burns with a flame front moving across the chamber towards the cylinder walls. The two important parameters for a spark ignition fuel are therefore flame speed and air:fuel ratio.

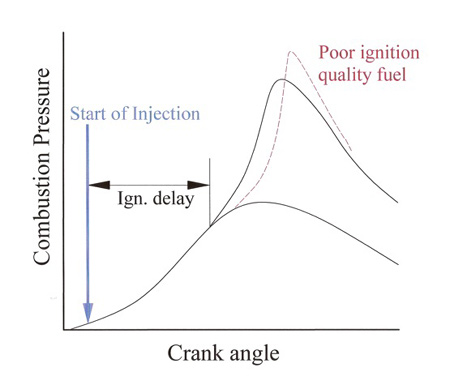

In a diesel engine combustion chamber, things are very different and much more complicated. Rather than having a flame front travelling across the chamber, the burning process is one of diffusion. Once the intake air has been compressed and heated to above the fuel's ignition point, and the fuel injected, fuel droplets penetrate the chamber and atomise along the way. At this point, and after a short delay, the fuel 'reacts' with the oxygen in the air, and spontaneous combustion takes place at the boundary where the fuel and air meet. Combustion takes place throughout the chamber and, once started, fuel will continue to be injected and the air motion within the cylinder maintained to ensure complete combustion.

But if characteristics such as 'knock' resistance, flame speed and heat of vaporisation are important for gasoline fuels then the equivalents for diesel fuel are ignition quality, density, volatility and viscosity.

The delay between the start of injection and combustion must be kept short, and is minimised by the use of high-cetane fuels (see RET-Monitor, Feb 2011). In diesel-engined road vehicles this cetane number is about 45-55, but the fuel specification used at Le Mans calls for that to be set to a maximum of 62. Not only does this reduce the ignition delay but the cycle-to-cycle variability is also enhanced.

An important consideration in any diesel fuel is its density, since the greater this is the greater the heating value, and heating value equals performance. But the greater the density then the greater the viscosity, and as fuel needs to be metered accurately - both in the volume supplied and its timing - this has to be kept within close bounds. The volatility of the fuel is also important. It's not necessarily directly associated with outright performance but ensures that the engine starts and that, when fully warm, the exhaust 'smoke' limit is not increased, limiting the potential performance of the engine. Whichever way you look at it, however, and just like gasoline, blending diesel fuel is full of compromises. But with Peugeot pulling out of Le Mans for this year, leaving only Audi and the huge advantage still gifted to them by the engine regulations, is there really much of a case for continuing with diesel race fuel?

Fig. 1 - Typical diesel combustion heat release diagram

Written by John Coxon