Dry sumps - the alternative

We live in a world of choice, or so our politicians would have us believe. But when it comes to engine oil systems for racing, is there anything other than a dry sump that can do the job? I would argue not, but despite that there are still authorising bodies or rule setters out there who insist on banning the systems, even though the alternatives are far inferior and these days probably no cheaper.

We live in a world of choice, or so our politicians would have us believe. But when it comes to engine oil systems for racing, is there anything other than a dry sump that can do the job? I would argue not, but despite that there are still authorising bodies or rule setters out there who insist on banning the systems, even though the alternatives are far inferior and these days probably no cheaper.

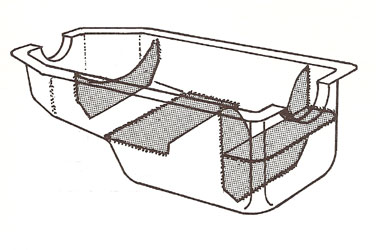

In the 1960s, a dry sump was totally unheard of outside the top echelons of the sport. At club level it probably meant a stone through the base of the engine and a trail of oil. To counteract oil surge in corners, competitors used to baffle the internal portions of the sump to delay, if not totally prevent, its onset. Horizontal and vertical plates would be welded into the sump in the hope they would prevent the oil from sloshing around yet still enable it to drain back to the pick-up pipe. Incidentally it was always the horizontal plates that seemed to be more effective than the vertical ones, presumably because they prevented the oil from disappearing up into the crankcase.

Sometimes volume had to be introduced by welding a monstrous selection of steel plates on the side, rear or front of the sump. The increased volume of oil thus created would ensure that under surge conditions at least some of it might reach the pick-up, and in so doing prevent total disaster. Ingenious swinging trapdoors could also be used, as well as what I think is the neatest idea of all - a swinging pick-up pipe, which floats around in the base of the sump and, hopefully, goes where the oil goes.

If restraining the oil in the sump or chasing it around could be considered as one choice, the other must surely be the use of some form of oil accumulator. Consisting principally of a giant piston and a spring/pressurised volume in a tube, the idea is to pressurise an amount of oil that can be released back into the main oil gallery, should the pressure in there fall momentarily. Fiendishly clever, the system can also be contrived to retain the pressure of the oil in its cylinder while the engine is stopped and then by opening some form of tap, releasing it into the engine and effectively 'pre-lubricating' the bearings before cranking.

Since the vast majority of wear takes place in the first few seconds of firing this is highly desirable. When regulations require competition engines to run with 'wet' sumps, the advantages of accumulators such as these can be very attractive.

Ingenious this might be, however, the big advantage of a dry sump is that it enables the engine to be positioned much closer to the ground. Removing the sump and positioning the oil in a more advantageous position not only enables the engine to be lowered but gives an opportunity to reposition the oil tank to benefit vehicle handling. Better cornering and reduced weight transfer under braking therefore gives the competitor so much of an advantage, and when systems such as this are so relatively inexpensive and work well, why make life difficult?

Fig. 1 - A baffled sump

Written by John Coxon