Fishy tales?

I was asked a question the other day that, for a moment, simply floored me. Strolling around an exhibition, my friend and I were talking about the stand we had just visited and the company’s claim that its camshafts were being ground to an accuracy of 3 microns (0.003 mm). “If they can grind camshafts to that level of accuracy,” said my friend, “why do I have to adjust the shims on the engine I am rebuilding?”

A simple enough question for the uninformed, you might say, but one that still left me a little bemused and confused – rather like asking, “Why do the pedals on a bicycle go round if a fish has no legs?” I decided this required more than a cursory reply, so I gathered my thoughts and prepared to explain.

“To start off with,” I began, “the accuracy of a grind refers to the dimensions of the camshaft profile actually ground compared with the values required from the design process. If the maximum lift of, say, your intake valve was calculated to be 10.000 mm on a direct-acting tappet then our camshaft manufacturing colleague was saying that their machine would reproduce that grind to a maximum of 10.003 or a minimum of 9.997 mm away from the camshaft baseline. Furthermore, all the profile lift dimensions to either side should be assumed in the band ±0.003 mm as well.”

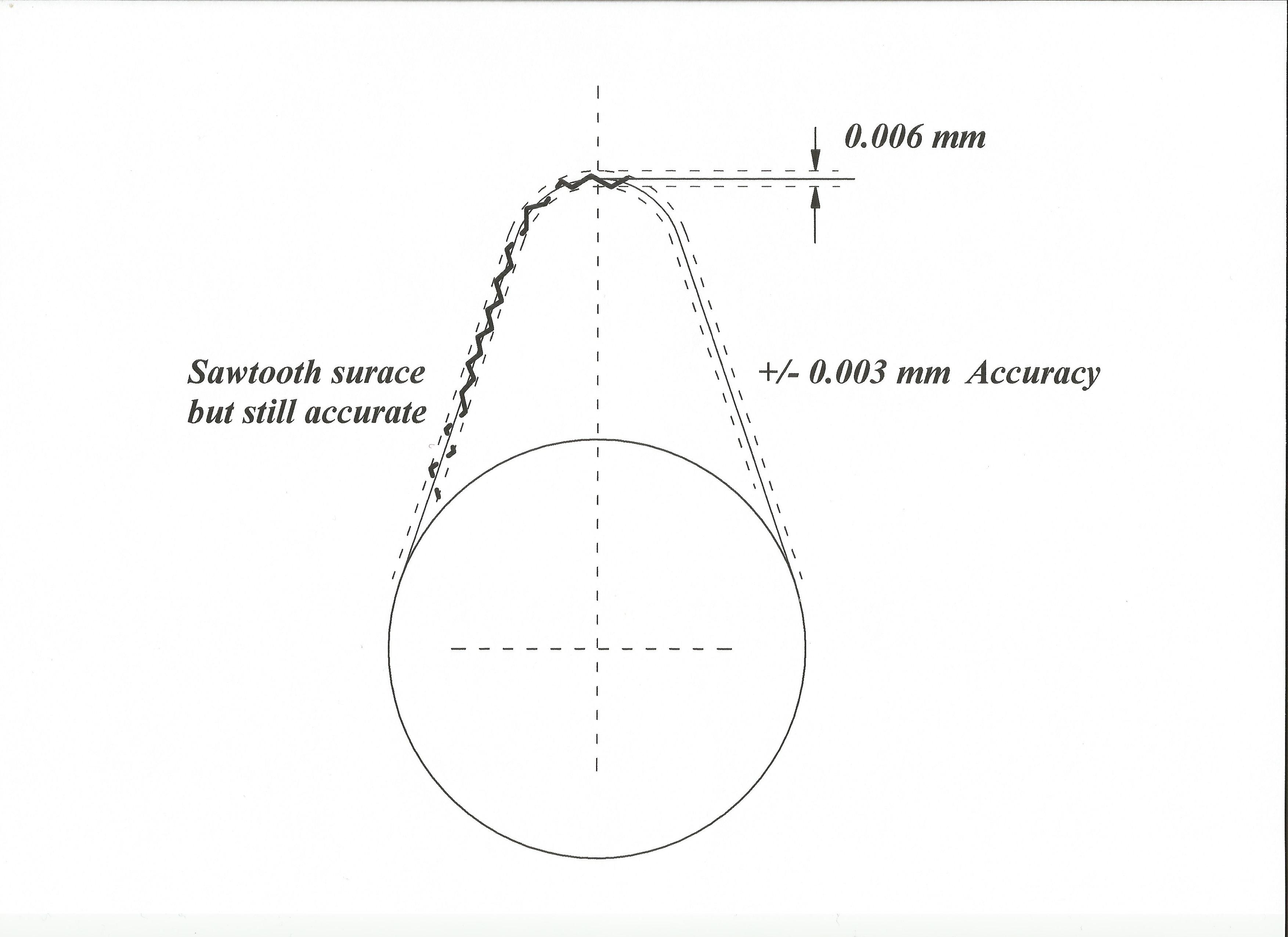

At this point I had to admit that camshaft profile designs were often supplied to six, even eight decimal places, so three decimal places – while impressive from a machining viewpoint, compared with the computed profile – might not particularly impress the designer. In addition, stating the ‘accuracy’ of the profile grind in this way doesn’t necessarily describe the ‘quality’ of the grind since the smoothness of the grind isn’t mentioned. While the grind could lie in a band ±0.003 mm either side of the desired profile, it could in theory still be a little like a hacksaw blade [Fig. 1], momentarily introducing high levels of acceleration and even higher rates of jerk, which in practice could result in many valvetrain issues. Although only really just a passing comment on the quality of their machines, what our camshaft friend should have stated was something on the smoothness of their cams; that would have meant so much more.

As to the question about tappet clearances, like my comment about fish and bicycles, tappet clearances and the accuracy of the cam profile are unrelated. Tappet clearances allow for differential thermal expansion of the valves and cylinder head so that the valve will always seat under all likely thermal conditions in the engine. And we adjust the tappet clearance using shims or graded tappets to take into account manufacturing variations so that initial contact between the cam profile and the rest of the valvetrain occurs at more or less mid-ramp at the beginning and end of the valve lift. But I guess you knew that anyway.

Fig. 1 -The theoretical hacksaw-like profile of a camshaft grind

Fig. 1 -The theoretical hacksaw-like profile of a camshaft grind

Written by John Coxon