Fuel for thought

Maybe I'm getting old but when I see racers the world over spending thousands of pounds (or dollars) on their winter engine rebuilds and then running them on ordinary pump fuels, I simply begin to wonder. By the time they have prepared the car, transported it to the circuit, paid the entry fee and fed and watered their little army of helpers, with any of the budget still remaining, you would have thought that they would have planned to fuel the engine on something just a little bit more suitable than pump fuel? OK, they might have been able to convince themselves that the particular pump fuel was the best they could find, but compared to many of the specially designed competition fuels now on the market, running your finely honed racing machine on a pump fuel is like - well, like an athlete running in carpet slippers, you simply don't do it.

Maybe I'm getting old but when I see racers the world over spending thousands of pounds (or dollars) on their winter engine rebuilds and then running them on ordinary pump fuels, I simply begin to wonder. By the time they have prepared the car, transported it to the circuit, paid the entry fee and fed and watered their little army of helpers, with any of the budget still remaining, you would have thought that they would have planned to fuel the engine on something just a little bit more suitable than pump fuel? OK, they might have been able to convince themselves that the particular pump fuel was the best they could find, but compared to many of the specially designed competition fuels now on the market, running your finely honed racing machine on a pump fuel is like - well, like an athlete running in carpet slippers, you simply don't do it.

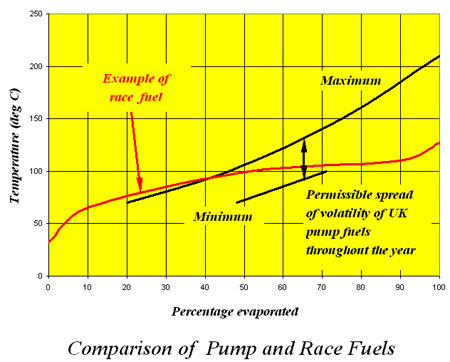

Pump gasoline you see, is a composite product made up from hundreds of different hydrocarbon compounds all carefully blended to a given performance specification. This means that it will have a minimum resistance to engine 'knocking', the octane quality (RON and MON) as well as maximum levels of hydrocarbons like olefins (alkenes) and aromatics. The octane quality is present to ensure that road going engines don't destroy themselves through premature ignition while the limits on the types of hydrocarbons has been regulated as a result of on-road vehicle emissions legislation. Introduced to underpin a minimum engine performance such a specification is not truly appropriate to a race engine. In Europe EN228 calls for a minimum RON of 95 while UK specification BS7800 raises this to 97 RON for Super unleaded. In addition to this, road fuels can vary from batch to batch, week-to-week and though suppliers will try to ensure a level of consistency, the amount of each hydrocarbon component will nevertheless still vary. During the year, summer or winter pump fuels will also be changed to suit the ambient conditions. In the winter the volatility will have to be increased because of the low air temperatures and this will require a greater proportion of lower boiling point constituents each with a differing octane value.

Race fuels on the other hand are altogether different. To start off with, race fuels will be specified to a maximum octane value. Regulated by the sporting authority in the UK these are 100 RON and 89 MON but in other countries may be higher. The fuel sold will therefore be much closer to the maximum limit than any minimum specified. Furthermore, every batch of fuel summer-to-winter, batch-to-batch or week-to-week will be precisely the same giving the same ignition properties irrespective of where and when purchased. Engine ignition mapping can therefore run much closer to the limits of combustion or if you prefer a higher level of safety on the base level tune. Because they tend not to incorporate the higher end components, racing fuels will also tend to burn faster and cleaner producing fewer in the way of carbon deposits keeping the engine cleaner and delivering more power for longer. If this wasn't enough, these faster burning characteristics mean less ignition advance and the probability that more of the fuel will burn inside the combustion chamber giving more power than simply releasing its heat into the exhaust port. With more power and a cooler running engine, tell me, what more could you ask for?

Even considering any marginal extra expenditure, you simply know it makes sense.

Fig. 1 - Volatility curve of a typical racing fuel compared to the limits for a pump fuel. Note how the curve is quite flat in the middle part indicating perhaps that the fuel has a higher proportion of fewer hydrocarbon components than would be present in a pump fuel.

Written by John Coxon