GF-5

The world of Formula One is a special case in the technology of engine lubrication. With formulations closely guarded and reputed to be radically different from those found on the service station forecourt, the philosophy behind them is to generate the minimum amount of friction commensurate with adequate component life. But when at one time engines could be changed between practice and the race, now with only eight engines allowed for the whole season the pendulum has moved away from minimising friction to enhanced durability, before - as will inevitably be the case - swinging back towards minimising friction again but with the higher level of wear protection at some future date.

The world of Formula One is a special case in the technology of engine lubrication. With formulations closely guarded and reputed to be radically different from those found on the service station forecourt, the philosophy behind them is to generate the minimum amount of friction commensurate with adequate component life. But when at one time engines could be changed between practice and the race, now with only eight engines allowed for the whole season the pendulum has moved away from minimising friction to enhanced durability, before - as will inevitably be the case - swinging back towards minimising friction again but with the higher level of wear protection at some future date.

In the real world of engine lubrication and the engines we use in our everyday life, these requirements are strangely very similar, but for one significant difference - that is, exhaust emissions or, to be more precise, exhaust system protection.

In the US and many other parts of the world, but not Europe, the automotive passenger car industry sees the introduction in 2011 of the ILSAC (International Lubrication Standardization and Approval Committee) GF-5 engine lubrication specification. Replacing the GF-4 specification, which came into effect around 2004 MY (Model Year), this latest in oil performance targets is designed to push the boundaries of passenger car factory-fill oils to new limits.

Designed to assist future CAFÉ (Corporate Average Fuel Economy) standards for passenger cars with higher oil quality, GF-5 formulations are also intended to be better at coping with the effects of the ethanol now seen increasingly in forecourt fuels. With increased levels of Group III base oils commonly found in many European ACEA specifications, more low-friction, 0W-20 formulations are therefore likely to be seen in service stations under the guise of API (American Petroleum Institute) SN service-fill specification from early next year.

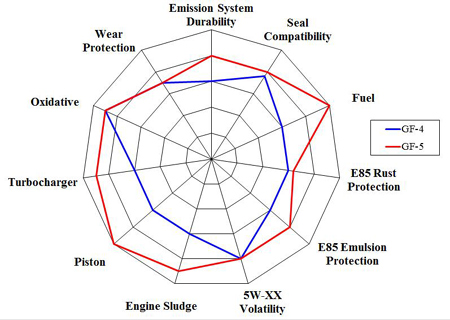

Apart from introducing new tests such as those for seal compatibility, improved E85 rust protection, better sludge protection and better piston cleanliness, the main aim of GF-5 has been towards fuel economy (as mentioned) and emission system (particularly catalyst) protection. For many years now, the presence of phosphorus in engine oil has been blamed for a gradual fall-off in catalyst performance throughout the life of a vehicle. Phosphorus, as many of you will know, is a major constituent of ZDDP, a highly effective anti-wear agent necessary for cam protection under boundary-layer and mixed-lubrication regimes.

For GF-4, the level of phosphorus in the oil was reduced to 0.08 % by weight. For GF-5 this limit is retained, but the amount of volatile phosphorus - that which is most likely to be 'boiled off' and find its way into the catalyst - is now limited. So while the amount of phosphorus is still reduced, at least there is some form of control over the amount of it retained in the oil, hopefully to lubricate the cam and piston ring later in its life.

While this might give a glimmer of hope for better cam wear protection on passenger cars, it is of little interest to the average competition engine builder. With no requirement for catalyst protection technology, a market now exists for low-viscosity 0W or 5-20W oils where the engine bearing size and clearances are acceptable but with much higher levels of anti-wear, ZDDP-type protection.

So while GF-5 factory-fill/API SN service-fill oils may be ideal for the new generation of fuel-efficient passenger cars, the time has surely come when oils for everyday transport and those for competition have diverged.

Fig. 1 - Comparison of ILSAC GF-4 and GF-5 oil performance

Written by John Coxon