Laser Peening

The use of amplified light has a great many applications in industry and beyond. Many of us reading this will do so having had our sight improved by laser eye treatment. In terms of the use of lasers in engineering, perhaps the most widespread application is laser-cutting, allowing sheet metal to be cut into any shape from a simple dxf drawing file. Many engineering works specialising in sheet metal will offer laser cutting nowadays. In a similar way, lasers are often used for part-marking purposes, from part and serial numbers to barcodes etc.

The use of amplified light has a great many applications in industry and beyond. Many of us reading this will do so having had our sight improved by laser eye treatment. In terms of the use of lasers in engineering, perhaps the most widespread application is laser-cutting, allowing sheet metal to be cut into any shape from a simple dxf drawing file. Many engineering works specialising in sheet metal will offer laser cutting nowadays. In a similar way, lasers are often used for part-marking purposes, from part and serial numbers to barcodes etc.

The benefits of introducing residual compressive stress into the surface of metal components is well-known and the excellent book on this matter by Almen and Black, is worth reading. The great benefit is the increase in fatigue strength that compressive stress can bring about. Whilst the in-service loads do not change, and therefore stress amplitude is maintained, these are superimposed on a lower mean stress. John Stowe recently wrote on the subject of CSP treatment which is another method of imparting compressive stresses to metallic components.

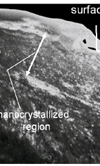

Laser peening is similar in principle to CSP in that it relies on pressure waves rather than the physical impact of hard particles to produce the stress. Compared to conventional shot peening, laser peening promises a very much deeper layer of compressive stress. Moreover, claims are made that the compressive stress due to laser peening is much less likely to be removed by the effects of temperature due to the lower levels of cold-working of the surface. These impressive claims are backed-up by the use of the process by the aerospace industry on fan-blades for both commercial and military applications.

The process itself is quite simple. A special tape or paint is applied to the area to be peened, and water is run over the surface. When the laser strikes the surface of the tape, high pressure plasma is produced locally, and the effect of the water layer is to contain the plasma, and acts to ‘focus’ the energy in the form of a pressure wave through the tape and into the metal underneath.

The disadvantages of laser peening compared to shot-peening are the cost and the level of complexity. Whilst it has been explained that the process is, technically-speaking, quite simple, its implementation is complex. It requires a programme to be written to precisely control the robots required to manipulate the laser and the workpiece. Owing to the fact that the laser ‘point’ is small and of a set shape (square), the control of where the laser is fired is critical. It is most definitely not a process capable of being applied manually. It is this complexity, allied to the high cost of the equipment and the programming costs that mean it is little used in motor-racing or motorsport in general. However, there are definite applications for this, owing to the fact that it can be precisely targeted. We can imagine that it would be useful for crankshaft fillet radii and oil hole exits as one example.

I’m certainly not aware yet of any applications of this in motor racing currently but, as costs decrease, it is likely to be examined in Formula One when there are some new engine regulations. Having encouraged one Formula One chassis supplier/engine constructor to look at this technique, I visited a UK laser-peening facility with them to review the technology for future applications.

Written by Wayne Ward.