Peace and harmony

I suppose you could say that the valvetrain in any engine is a bit like my grown-up family. So long as everyone away from home stays in contact with the matriarch, all is well. However, as soon as that contact is lost - a late birthday card, for instance, or a promise to phone not honoured - then there are, shall we say, consequences. The same can certainly be said of the valvetrain, for when components in the system lose contact with each other the consequences can be more than simple admonishment.

In designing a cam profile, the normal intention is also to supply springs of a sufficient rate to keep the follower in contact with the cam lobe as it slows the valve down towards peak lift. The higher the rotational speed of the cam, the greater the spring force required, to the point where for a given profile, the cam and follower will eventually separate. This condition is generally known as valve 'float', and as a broad rule cam designers tend to make this around a couple of hundred rpm above the maximum speed of the engine.

But that is not the only condition when the prescribed motion of the valves, as dictated by the cam, can be lost. If we strike an empty cup with a spoon then the frequency of the resulting sound will correspond to the natural or resonant frequency of the cup. Likewise, when continually bounded by the rhythmic action of the cam, the valvetrain in its entirety will also have a natural or resonant frequency - indeed, there may be more than one resonant frequency, because there may be many components, each one having its own.

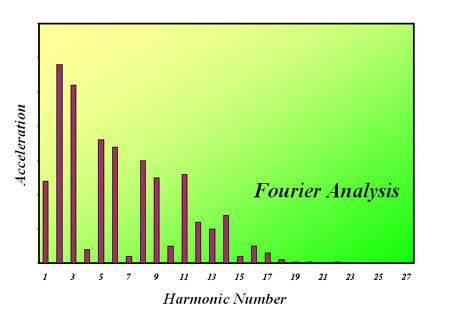

Transferring our attention to the cam, if we then undertake a Fourier analysis of the cam acceleration curve (Fig. 1) then much information can be revealed. For those not too familiar with the finer points of mathematics, Fourier analysis takes any continuous geometrical curve and splits it into the amplitudes and frequencies - or, more exactly, orders of frequencies - of sine waves that make up the curve.

This is very useful when we need to understand the dynamics of our valvetrain, and particularly the valve spring, since it too will have a natural frequency of vibration which, if excited, will affect the motion of the valve. As cam profiles become more aggressive, the higher frequency motions that make up this Fourier sequence can excite the valve spring at engine speeds well below those designed for valve 'float'. Lovers of the YouTube website can see amazing video footage of this and what happens to valves and valve springs when their natural frequencies have been reached.

Generally speaking, valve springs have natural or resonant frequencies in the 350-600 Hz bandwidth, so whenever possible the more significant of these harmonics should be designed to fall outside the resonant frequencies of the chosen valve spring. Twin valve springs and variable rate springs are but more attempts for the designer to 'tune' this spring to the harmonics of the cam profile, and in successfully doing so peace and harmony will result.

I only wish that requesting older siblings to phone their parents on a more frequent basis were as comparatively easy.

Fig. 1 - Fourier analysis of the camshaft acceleration

Written by John Coxon