Plumbing the depths

Readers of my recent RET-Monitor on electrics will know of the trials and tribulations of the fuel system on a certain track car. Having solved that particular issue, and with the season coming to a close, the owner thought it advisable to review the whole fuel system and perhaps, following that, update the vehicle to run on fuel injection in place of rather ancient current carburettor technology. In renewing the fuel system these are some of the issues to be faced.

Fortunately, and for the sake of simplicity, the vehicle in question has only one tank, situated more or less alongside the driver. The problems of feeding from two or more fuel tanks are therefore thankfully avoided, although the problems of fuel surge within the tank when cornering are not. The tank will be of a safety bladder variety inside an aluminium skin, much resembling, as far as aesthetics are concerned, the current aluminium unit but far safer in the event of a major accident. Just because such an accident has never happened to date doesn’t mean it won’t, and since the driver values his skin (but probably not as much as the rest of the vehicle) the added cost as well as the extra weight is a penalty simply to be endured.

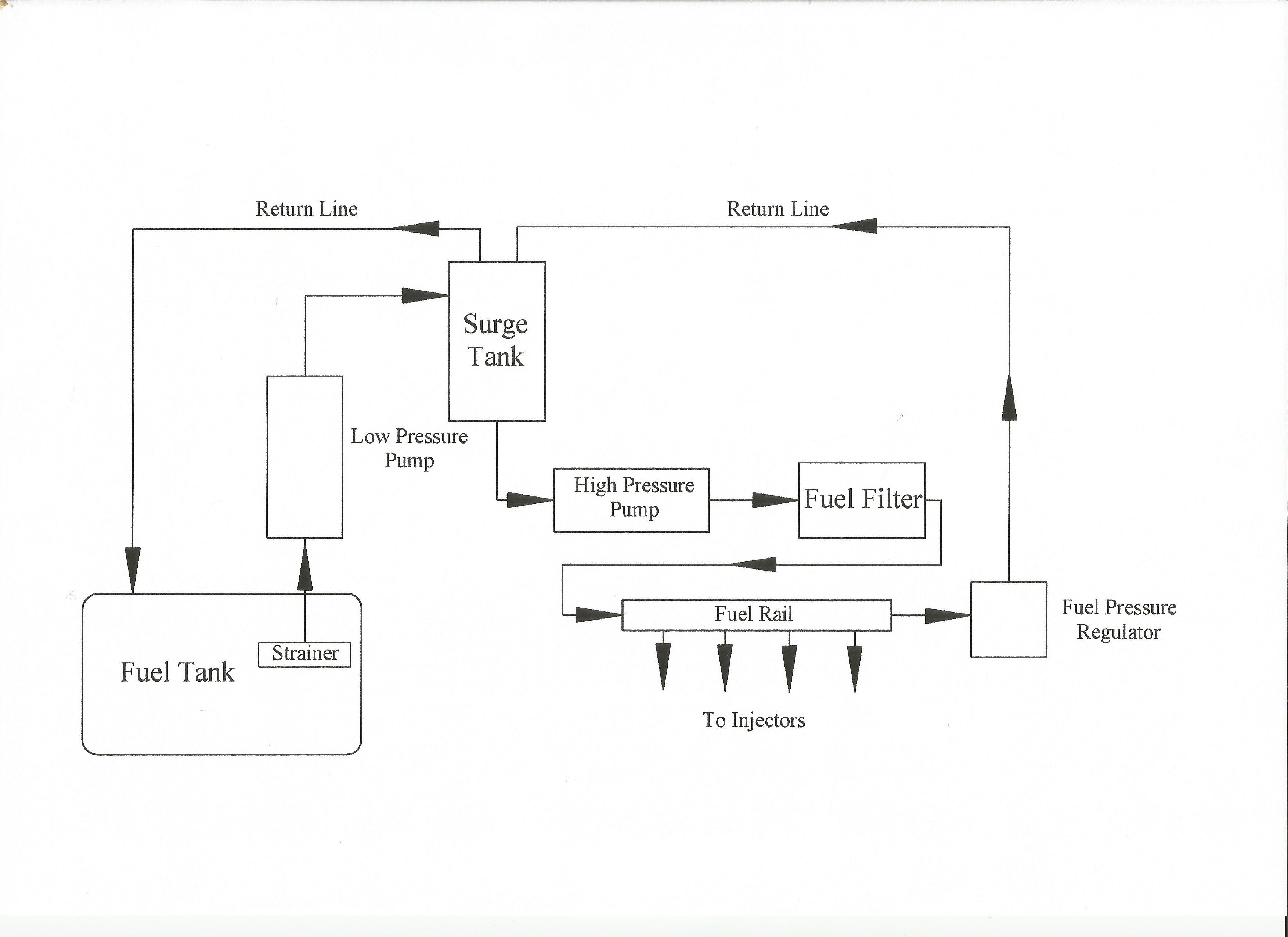

Inside the tank is the first dilemma. Do we include a series of trapdoors leading to a single make-up tank where the sole lift/high-pressure pump will be situated, or do we dispense with that and fit a simple low-pressure lift pump and send the fuel to a smaller, half litre or so ‘surge’ tank? Whichever in-tank pump we select, it will be fitted with a simple coarse gauze strainer to remove the larger pieces of debris, rust or dirt.

No matter how careful you may be in transferring the fuel from bulk storage into jerry cans and then into the vehicle tank, there is always the risk of small grains of rust or dirt contaminating the system. While pumps may be tolerant to a certain extent of smaller foreign bodies (say >30 microns) the fuel injectors are not so, so at some point in the system a much finer filter will need to be installed. And here is the next dilemma: where do we install the second, much finer filter – immediately after the-low pressure lift pump and before the surge tank, or after the high-pressure (up to 6-10 bar) pump and before the injectors?

In essence, I suppose it all comes down to convenience, personal preference or simple packaging in the vehicle, but placing it after the low-pressure lift pump pumping into the surge tank protects the high-pressure pump from the finer debris (down to, say, 25 microns). In this position, however, there could be circumstances where the filter places some kind of restriction or depression on the intake to the pump, and when pumping volatile fluids this is never a good idea.

As a general rule, I have always maintained that any filter should be placed on the high-pressure side of the pump. Although the filters used have large surface areas over which the filtering takes place, placing them after the high-pressure pump minimises the chance of vapour lock or cavitation as a result of any depression (however slight) should you place it on the intake side, but also ultimately protects the injectors (and hence engine) should the fuel pump fail for whatever reason. For much the same reasoning of vapour lock, the high-pressure inline pump should always be placed as low as possible in the chassis and the surge tank mounted above it.

Although apparently simple, the design of the fuel system has to be carefully thought out.

Fig. 1 - Fuel system

Fig. 1 - Fuel system

Written by John Coxon