Super Finishing Metals

For years now, race component manufacturers have closely guarded their proprietary metal super finishing processes. Using increasingly finer grinding mediums to produce the desired surface finish whilst still complying with the precise geometric requirements of the component.

For years now, race component manufacturers have closely guarded their proprietary metal super finishing processes. Using increasingly finer grinding mediums to produce the desired surface finish whilst still complying with the precise geometric requirements of the component.

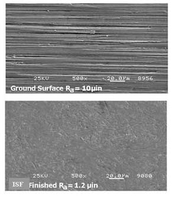

Grinding is the traditional final metal finishing operation performed on engineered metal-to-metal contact surfaces such as roller bearings and some gears.

It results in a surface with a unidirectional ridged pattern that corresponds to the direction of the final grinding operation. However, as was quickly discovered, grinding with successively finer grinding wheels is expensive, repetitious and ultimately ineffective. It simply results in a surface that has more, closer-spaced rows of shorter height asperities. When placed into operation for the first time, ground components have a minimal area of initial metal-to-metal contact at asperity peaks where contact stress is concentrated.

In the past various ‘rumbling’ processes have been used to further reduce these asperity peaks. These processes use an abrasive medium carried in a water-based liquid all contained in a vibrating bowl. The agitation caused by the vibrations causes the medium to abrade the surface of parts immersed in the mix. This is a relatively non-discriminatory, uncontrolled process that can change the surface geometry, attacking only the surfaces that can be accessed by the medium itself and often leaving critical areas such as corner radii and cavity features untouched. Acceptable, maybe, for a relatively coarse deburring operation, but achieving little else in the way of a super finished surface.

In a novel approach to super finishing, REM Surface Engineering of Brenham, Texas developed and patented a unique process called Isotropic Superfinish or ISF. The ISF process is a chemically accelerated finishing process. It uses the same vibratory finishing equipment as the rumbling process but replaces the abrasive media with a high-density, non-abrasive media that in combination with specific chemicals “weaken” or oxidize the tips of the asperities.

The process is not a polishing process but rather a controlled surface finishing process. The REM procedure involves two steps. The first step, referred to as the ‘Refinement Process’, involves a chemical interaction on the surface of the part. The active chemicals compounds create a thin, oxide film on the parts surface with a pH value of between 1.6 – 5.5. Due to the vibratory action in the work bowl the ceramic media ‘wipes’ off this oxide film. The chemically induced film re-forms only at the peaks that are interacting with the vibratory media, and the process repeats itself. Over time this action removes the peaks leaving only the valleys. These remain intact and serve as a necessary reservoir for the lubricant.

The process continues – with the constant addition of fresh compound – until the required surface finish of Ra 0.02 µm or Rz 0.2 µm is achieved.

The process continues – with the constant addition of fresh compound – until the required surface finish of Ra 0.02 µm or Rz 0.2 µm is achieved.

The second step is referred to as the ‘Burnish Process’. After the required micro finish is achieved, a mild alkaline mixture is introduced. After a relatively short period a polished, chrome-like finish is produced. In addition to the polishing effects, this step effectively removes all traces of the film formation from the refinement process.

Because asperities have been removed, parts that have been isotropically prepared have an improved, highly random, metal-to-metal contact pattern. The final surface is smoother, and the contact stress in any one location is diffused over a wider area due to the improved contact pattern. Among its many benefits, an ISF surface reduces friction and wear, increases part durability, and improves corrosion resistance. The process has proven applications in many industries including aerospace, automotive, gearing & bearings, medical, military and has become the super finishing process of choice in all areas of the motorsports world.

Written by David Wood.