The carburettor

Any engine man these days, no matter how young or old, will have at least a pretty good idea of how electronic fuel injection works. With its speed, temperature and pressure sensors, maps and ECUs, the digital nature of the technology is well understood by many. Go back though say, 40 years and although a good many so-called engine tuners will have thought they knew about fuelling systems, when it came down to it, the complexities of the carburettor required a very special kind of knowledge.

Take the fixed-jet carburettor for instance, a device that young boys and old men used to drool over until they tried to re-jet - or, as we used to say, 'tune' it. Its idle jets, its progression, main jets and accelerator pump offered a myriad of ways of getting it wrong. Take the idle system, for one. With an idle jet, idle mixture adjustment screw and the engine idle speed controlled by the position of the butterfly (yet another screw) eventually it would be possible to get the engine running sweetly at the correct mixture and speed. However, for highly tuned engines the quality of the engine idle and its general roughness sometimes made life a little more difficult.

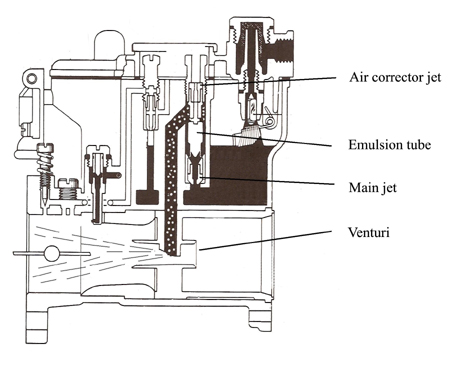

The main fuelling circuit was equally tricky. For this we had the auxiliary venturi, which provided the signal for the main jet, the air correction jet and the emulsion tube. Air passing through the auxiliary venturi created a negative pressure, which drew the fuel up from the float chamber through the main jet and then down again to be 'sprayed' - or more likely 'spluttered' - into the venturi. At the same time, air was drawn in through the air correction jet, mixed with the fuel via the emulsion tube and passed down with the fuel in the form of a fuel-air emulsion. This air assisted the fuel's atomisation as it entered the engine intake air and, together with the downstream throttle plate, broke up the fuel droplets to give a more homogeneous mixture.

In a simple fixed carburettor the main fuel jet will, if set to the correct setting at low speed, generate a much richer mixture as the engine speed increases. The air corrector jet on the other hand, has a much greater effect at higher engine speeds, and is incorporated to offset this enrichening tendency. The target for adjusting the main jet and the air correction jet is to produce an air-fuel ratio that is as close to constant as possible throughout the engine running range at both wide-open and part throttle.

To many, however, the emulsion tube is a bit of a mystery and from my observations at the time, few really knew much about them, often adjusting only the main and air correction jets. Although a form of mixing chamber, the emulsion also alters the mixture as the amount of fuel is restricted by the main jet lowering the fuel level in it and uncovering more of the air bleed holes. The emulsion tube can therefore increase the mixture enrichment at low speed or weaken it at low speed. It can also enrichen it for slight accelerations by altering the external diameter of the tube. It all depends on how it is designed.

With the complexities of the idle circuit along with those of the main system, it is no wonder that carburettor tuning was better left to the experts.

Fig. 1 - The fixed-jet carburettor

Written by John Coxon