The importance of air filtration

The primary function of the engine air filter is simply to remove airborne contaminants – road or trackside dust, dirt, tyre and other organic detritus in the environment – from the intake airstream and prevent it from entering the combustion chamber. Once inside the combustion chamber, much of what isn’t consumed by the advancing flame front will find its way out through the exhaust system and eventually out of harm’s way.

However, what is left will inevitably become either trapped between the moving parts of the engine, creating wear, or hopefully be flushed away by the lubricating oil. In the former, engine performance will deteriorate; in the latter, such debris may be transferred to other parts of the engine to wreak havoc elsewhere. Given that studies have shown that of that debris left behind after combustion, 30% passes out through the exhaust and 50% goes into the oil, a worrying 20% remains unaccounted for. So whichever way you look at it, the presence of any particulate matter in the engine’s intake air is undesirable.

As we know though, dust and dirt comes in all shapes and sizes, and to develop a filter to take out all of these contaminants is simply not feasible. To minimise engine wear therefore it is necessary to target those particles that are most likely do damage based on their size, shape and/or roughness and hardness.

You might be surprised to know that, according to studies in the US, the average amount of airborne dust and dirt in clean highway conditions is something like 0.1 mg per cubic metre of air. Computed to a 2.0 litre engine over 100,000 miles, that amounts to about 30 g of dust or dirt over the period. In the much dustier conditions at track or offroad venues, with concentrations near 5 mg per cubic metre all the way up to 5000 mg per cubic metre, clearly the importance of an air filter cannot be understated.

The particle size distribution of this dust and dirt is also highly revealing. Described as ‘of a bi-modal distribution’, highway samples have shown that the fine mode lies in the 0.1-2.5 µm range, while the coarse range is something nearer 2.5-30 µm. When you move to off-highway air contaminants then, as you might expect, the particle size increases enormously, with 100 µm being not that uncommon.

The inevitable conclusion to any work on correlating engine wear with particle size is that the situation is highly complex. The larger the particle then clearly the greater the risk, but since the dynamic running clearance between adjacent components throughout the engine will be in the 0-20 µm range, anything that can fall into this region is of concern, as indeed also is its relative hardness. With oil film thicknesses of the order of 1 µm (and getting thinner in the search for higher engine efficiency), any particle thicker than this has the potential to cause damage.

But despite all this there are no universal air intake filter standards in the automotive sector – at least not that I am aware of. Individual vehicle/engine manufacturers will have their own standards, and these will have been developed over time and shared with their OE suppliers. Tests will have been carried out using various ISO-standard dusts, and the filtration efficiency reported. But since the relationships with their component suppliers will often run well into the service life of their vehicles, these standards are not widely publicised. And since engine issues attributable to poor air filtration are rarely if ever reported, the attitude taken tends to be, ‘If it ain’t broke then we won’t fix it’.

And so, based on all this, the only recommendation I can give is this: use a filter and change it or (if of the re-useable type) clean it regularly. Only then can you be confident of getting clean air into your engine.

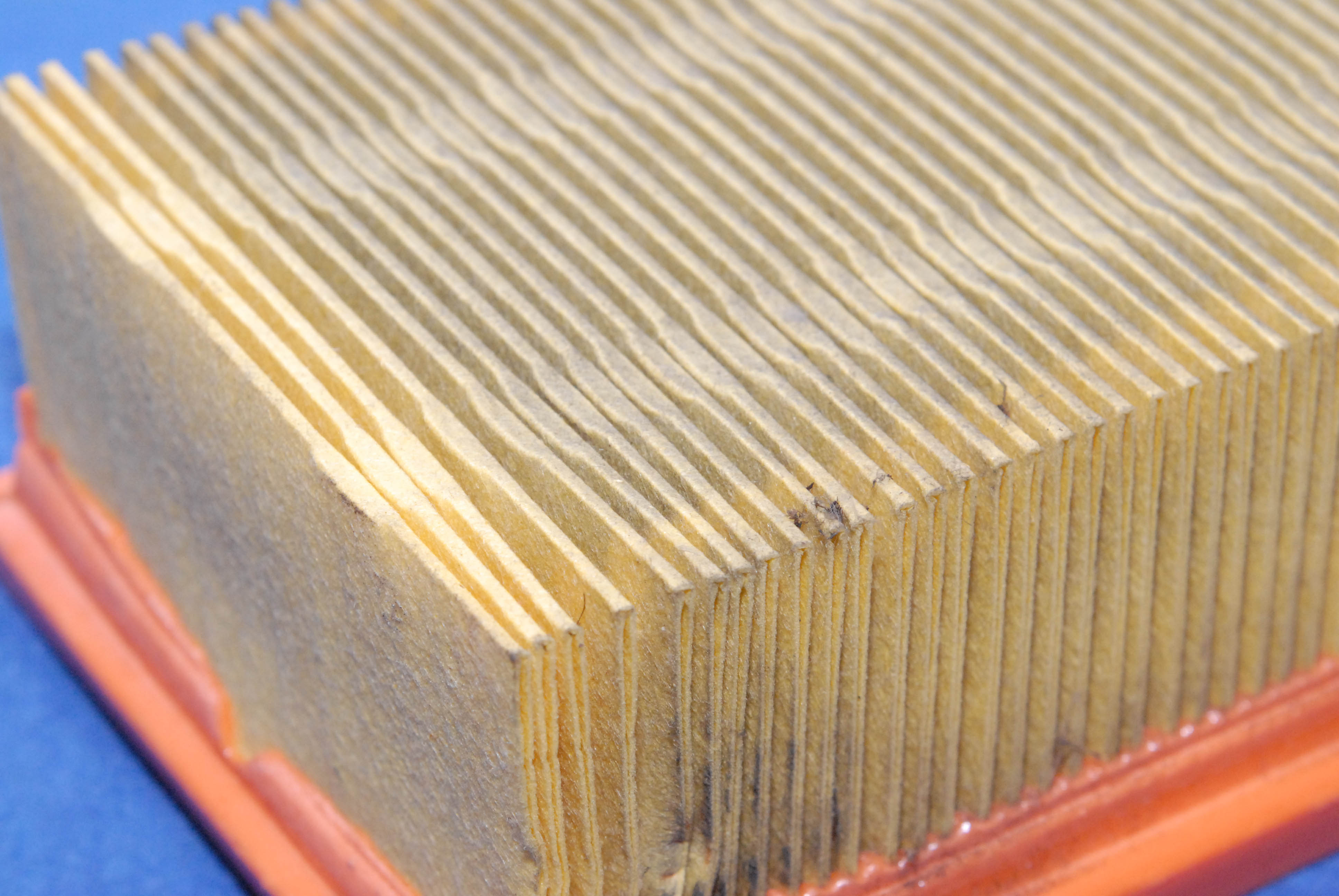

Fig. 1 - A used air filter showing the dirt that would have otherwise passed into the engine

Fig. 1 - A used air filter showing the dirt that would have otherwise passed into the engine

Written by John Coxon