The Lord of Rings

Of all the components in a race engine, the top or compression ring has probably the hardest task. Although its primary purpose is to seal the combustion chamber from the crankcase below, this role is somewhat complicated by the requirement to dissipate the vast majority of the heat in the piston and to do so under the most trying of dynamic conditions. Positioned as close as possible to the top of the piston crown as is technically feasible, it is suggested that as much as 80% of the heat in the top of the piston, is conducted through this ring and into the cylinder wall.

Of all the components in a race engine, the top or compression ring has probably the hardest task. Although its primary purpose is to seal the combustion chamber from the crankcase below, this role is somewhat complicated by the requirement to dissipate the vast majority of the heat in the piston and to do so under the most trying of dynamic conditions. Positioned as close as possible to the top of the piston crown as is technically feasible, it is suggested that as much as 80% of the heat in the top of the piston, is conducted through this ring and into the cylinder wall.

For sprint engines to minimise friction this job is done by a single steel or cast iron ring. But when durability is an issue, this role will be shared with a second ring of a totally different design, reflecting its dual role supporting the oil control ring below it.

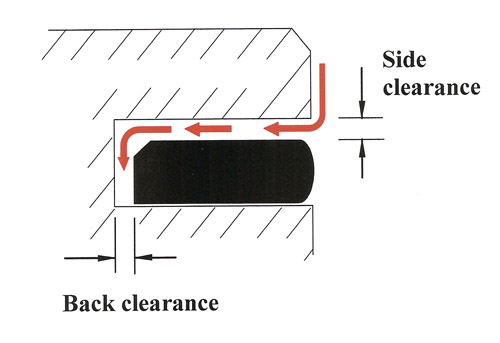

Since the primary task of the top ring is to seal, many believe that this is because of radial tension holding it against the cylinder wall. While it is true that this tension is an absolute necessity, it is the combustion gas pressure flowing past the piston top land and getting behind the ring that is the key action. As well as ensuring that no gas gets past the ring at its outer contact with the cylinder wall, the clearance between the top of the ring and the piston, usually referred to as the ‘side clearance’ has to be sufficient to allow the gas to flow quickly through into the space at the back. If this side clearance is too large then under the dynamic loads the ring maybe able to move and distort uncontrollably to the detriment of the seal at the cylinder wall. Such a phenomenon is known as ‘ring flutter’ and usually occurs at high engine rpm when it will inevitably lead to excessive piston blow-by and reduced engine performance. Eventually this will lead to burnishing of the ring faces when heat cannot be dissipated and in the extreme can lead to melted pistons and that sickening sound of an engine when things go drastically wrong. Piston ring manufacturers generally recommend that this side clearance should be something around 0.001 to 0.002 inches (0.025 – 0.05 mm) depending upon the piston and ring profile.

Along with this ‘side clearance’ comes the ‘back clearance’. In order to ensure that the gas can get behind the ring it is imperative that this ‘back clearance’ should be at least 0.005 inches. Much more than this and it will take longer for the gas to accumulate and push the ring outwards on the power stroke. Any less and it may not function as designed at all. However, for all the above to work as planned it is imperative that the underside of the ring and corresponding ring groove surface are both flat and smooth to the highest standards. This should produce a gas tight seal and ensure that the gas doesn’t escape past the ring land and into the crankcase via a different route.

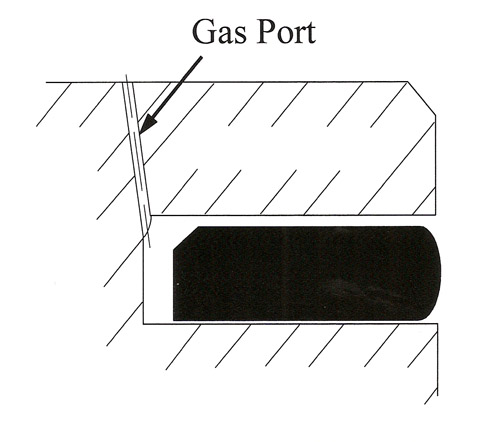

In certain applications where the ultimate in ring control is required (such as some forms of drag racing when very high engine running speeds are normal), this side clearance is reduced to a minimum and a number of very small ‘gas ports’ drilled vertically down from the piston crown into the back of the ring groove. These 1 mm diameter holes when drilled equidistant around the crown will enable the combustion gas to get behind the top ring without the need to travel down the piston top land and by way of the side clearance. Consequently this side clearance can be reduced but since these gas ports are likely to fill up with soot very quickly, this approach should only be entertained when engines are rebuilt on a highly frequent basis.

As racers we’re all too familiar with the idea of checking the engine top-end on a regular basis. However in view of the critical influence of the compression ring, shouldn’t we be checking this as well?

Written by John Coxon.