The Naming of Parts

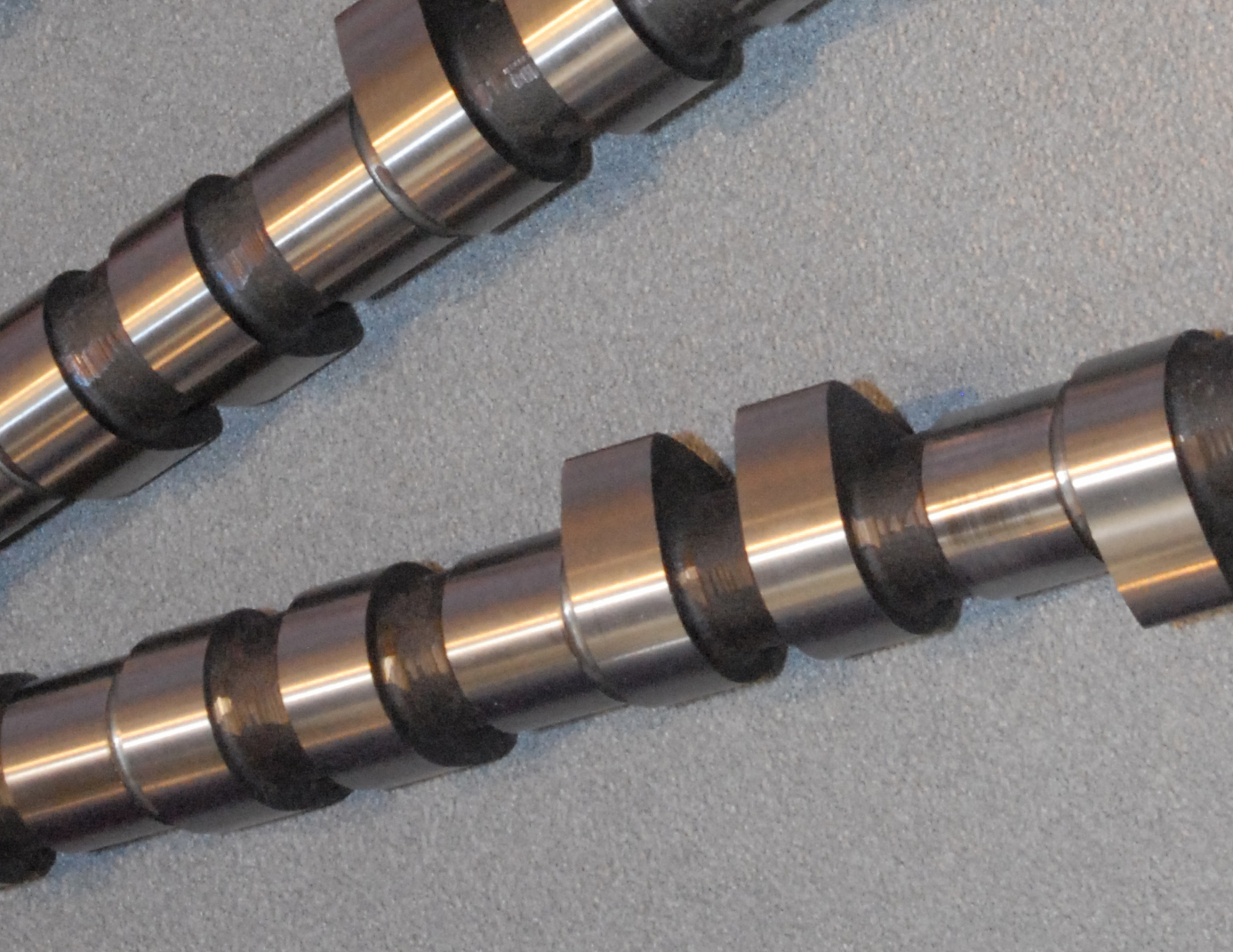

The heart of any internal combustion gasoline engine just simply has to be the camshaft and the valve mechanism it controls. Designed to maximise the amount of air entering the cylinder at a range of engine speeds, it is often perhaps the first port of call when seeking to improve engine performance. In theory, and in an ideal world, the inlet valve should open to its full lift precisely at piston top dead centre and then close again when the piston next comes to rest at bottom dead centre. Apart from assuming that the intake charge has no inertia this also assumes that the inlet valves themselves

The heart of any internal combustion gasoline engine just simply has to be the camshaft and the valve mechanism it controls. Designed to maximise the amount of air entering the cylinder at a range of engine speeds, it is often perhaps the first port of call when seeking to improve engine performance. In theory, and in an ideal world, the inlet valve should open to its full lift precisely at piston top dead centre and then close again when the piston next comes to rest at bottom dead centre. Apart from assuming that the intake charge has no inertia this also assumes that the inlet valves themselves

have little or no inertia and hence the forces involved in the valve train are negligible. Those of us in the real world know that this isn’t the case and that somewhat inconveniently, the forces involved in opening and closing these valves can be substantial. To compensate therefore the process of lifting the valve starts some time well before Top Dead Centre and as such will not be back in place until well after Bottom Dead Centre. Thus the valve has to be lifted off its seat, fully opened and then closed again placing it gently back on its seat smoothly and without introducing any undesirable motion, all in the space of a fraction of a second.

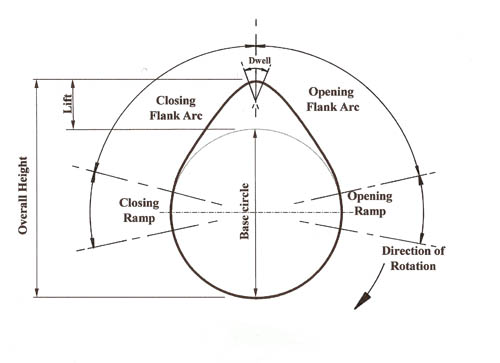

In order to fulfil this function, cam designers split their cam profile design into a number of separate regions, which can be characterised in terms of lift, velocity, acceleration and rate of acceleration (or deceleration – negative acceleration) referred to as jerk. Each region has to seamlessly blend into the next to ensure that no unnecessary forces are introduced that could generate excessive contact stresses or overcome the spring force ensuring the precise control of valve train components and avoiding separation under all running conditions. While older cams may have been designed using long and tedious techniques involving hand calculated, trigonometrical methods, modern cam computer design packages use the theory of spline functions giving almost infinite flexibility in the shape of the acceleration curves that can be produced.

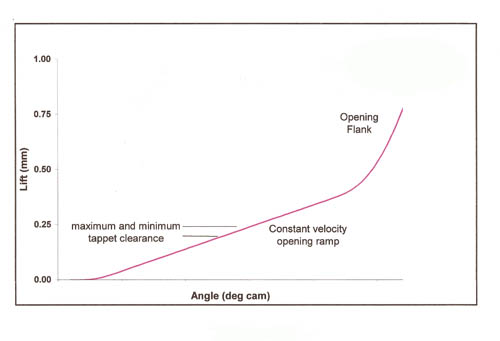

To understand some of the issues faced by the designer the cam profile can be split up into a number of parts or zones each with it separate function. The first of these are the ramps – both opening and closing. The purpose of the opening ramp is to enable the valve gear to be lifted up off the base circle at a known velocity. Mechanical tappets need to have some running clearance to ensure the valves are fully seated for much of the engine cycle and the function of the ramp is to take up this clearance with minimal impulsive force. Likewise the closing ramp which in many cases is longer, needs to drop the valve carefully back on its seat and is particularly important for the exhaust valve, to preserve a critical level of durability at the higher temperatures involved. Most competition cams tend to use constant velocity ramps and when using mechanical tappets the height of this ramp dictates the valve lash setting.

Once the valve has been picked up by the ramp it moves quickly into the opening flank. Arguably the most important part of the design, this aspect controls the acceleration and eventual velocity of the valve train, which then has to be slowed down by the action of the valve spring if separation is to be avoided approaching peak lift, resulting in valve ‘float’. In general the faster the valve is opened for a given valve opening duration the more air will flow. When the valve reaches full lift it will stop moving prior to dropping backwards towards the seat. This period, referred to as the ‘Dwell’, needs to incorporate as large a nose radius as possible to minimise contact stresses when hydrodynamic lubrication is at a minimum. Once over the peak the valve spring continues its task of keeping control over the system until the valve is fully closed.

Although the principle of the camshaft is in itself very simple, the practicalities of implementing such a system are far from it.

Written by John Coxon.