The Napier ring

Mention the word 'Napier' to many people and the chances are you will be met with a quizzical stare. To some, mainly engineers and scientists with an interest in history, they will talk of John Napier, the 16th century scholar and inventor of logarithms. To others, Napier is associated with rather large, industrial-type turbochargers or the classic range of multi-cylinder piston aero engines that were around just before the jet engine took over, such as the iconic Napier W12 Lion or the incredibly complex H 24 Sabre, both now considered works of art.

Mention the word 'Napier' to many people and the chances are you will be met with a quizzical stare. To some, mainly engineers and scientists with an interest in history, they will talk of John Napier, the 16th century scholar and inventor of logarithms. To others, Napier is associated with rather large, industrial-type turbochargers or the classic range of multi-cylinder piston aero engines that were around just before the jet engine took over, such as the iconic Napier W12 Lion or the incredibly complex H 24 Sabre, both now considered works of art.

To piston designers, however, the name means only one thing - a particular design of scraper ring common in many ring packs and used to control the amount of oil on the cylinder bore.

In a typical three-ring piston design the Napier ring is invariably used in the second ring position. The top compression ring takes all the gas loads and heat generated as a result of combustion while the oil control ring at the other end controls the lubricating oil attached to the cylinder bore, returning it through the side of the piston to the sump.

The task of the centre ring, often referred to - quite erroneously in some people's eyes - as the lower or second compression ring, is a combination of both. It further controls oil that has escaped the oil control ring, and at the same time reduces still further the amount of combustion gas travelling towards the sump. In fact recent studies have suggested that up to 85% of its activity is oil control while only 15% is gas control. The ring is therefore essentially scraping off the excess oil and allowing only the minimum through to ensure adequate lubrication of the top ring.

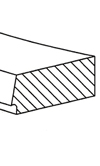

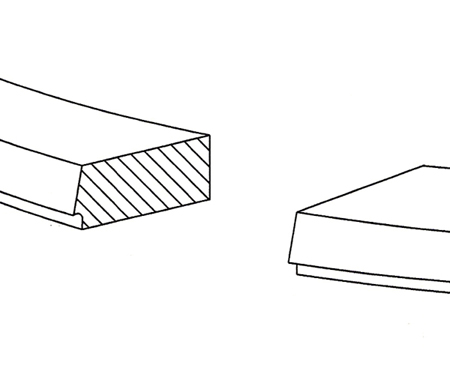

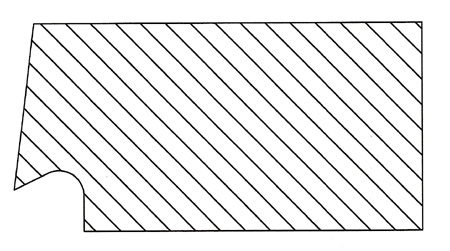

While simple scraper rings can suffice, the Napier ring is perhaps the most common of those used and comes in two basic forms. The first is essentially a rectangular cross-section recessed at the bottom outer surface, while the second is similar but incorporating a slight taper on the outside face. The result is a sort of hook or claw in cross-section as the inner face is undercut.

When installed, this latter version creates a continuous line of contact around the surface of the cylinder bore, maximising the contact pressure but minimising the actual friction load even when the ring twists, as it will invariably do. This narrow line of contact also ensures rapid bedding-in and, shielded from the excessive temperatures of the top ring, it is therefore usually made from cast or ductile iron.

The great advantage of the Napier scraper cross-section in comparison to a simple scraper ring is its ability to store oil just below its lip. This ensures that there is always a space for any excess oil to flow, and prevents any potential for the inter-ring pressure to build up and force its way past. Thus a three-ring piston with a Napier ring as the bottom compression ring will always have better oil consumption than other designs.

This, however, tends to be at the expense of increased exhaust gas blow-by. Furthermore, such designs can be adjusted to suit the application by altering the size of the oil storage volume to ensure oil is removed quickly away from the bore.

John Napier's invention of logarithms simplified the world of mathematics and astronomy. In the piston ring the name 'Napier' is equally significant.

Fig. 1 - Napier ring

Fig. 2 - Cross-section

Written by John Coxon