The return of Viscosity Index

At the time of writing, with two high-speed superspeedway events under their belts, oil formulators for NASCAR are at last breathing a sigh of relief. Since the fuel for this year has been revised to include 15% ethanol, subsequent post-race engine oil analysis has shown that there is no unexpected deterioration, and piston wear - although higher for the high-speed plate engine tracks - is no more than expected. But if we are honest, that was only of passing interest. With many events around the world using similar blends, the effects of ethanol on high-performance engines is now well documented.

At the time of writing, with two high-speed superspeedway events under their belts, oil formulators for NASCAR are at last breathing a sigh of relief. Since the fuel for this year has been revised to include 15% ethanol, subsequent post-race engine oil analysis has shown that there is no unexpected deterioration, and piston wear - although higher for the high-speed plate engine tracks - is no more than expected. But if we are honest, that was only of passing interest. With many events around the world using similar blends, the effects of ethanol on high-performance engines is now well documented.

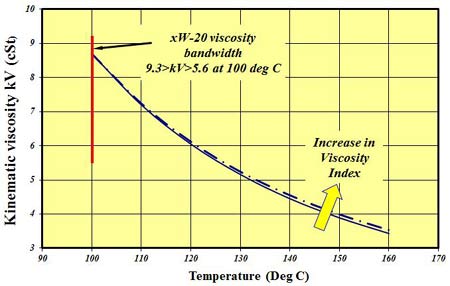

The real concern for the formulators is the increasing exploitation of the two-car draft when two cars, literally running nose to tail, bumper to bumper, can gain so much extra speed and effectively run away from the pursuing pack. The car in front runs in clean air, and engine coolant/oil temperatures of about 220-230 F (105-110 C) will be typical. The car behind, however, almost totally excluded from any form of cooling air, will see temperatures much nearer 300 F (150 C). Running ten to 12 laps at a time in this way, on and off throughout a 500-mile race, puts serious demands on the engine oil.

Drafting of course is nothing new; we are all familiar with multi-car crocodiles snaking their way around the superspeedways. Positioned only a few feet apart as engine temperatures rose, drivers would jink to one side to pick up cool air before ducking back under again and regaining their tow. But as the advantages of tucking right underneath the rear spoiler of the car in front have become more readily appreciated - despite the potential damage to the engine - engineers have been forced to look at ways of making the engines last. For the lube oil supplier this means making sure the oil is at its optimum viscosity for the entire race and with the minimum of degradation, despite these temperature changes.

As a rough and general rule, the higher the oil viscosity in an engine, the greater the protection it offers, but this comes at the expense of friction. Too low a viscosity and the oil film breaks down, and wear will result; too high and you lose power. In formulating engine oils, therefore, the idea is to run at the lowest possible viscosity compatible with an acceptable amount of wear.

Running at 300 F for long periods rather than 230 F, oil blenders need to re-blend their normal PAO/ester blends for the superspeedways to take this into account. One way of doing this would be to re-blend the oil by increasing the amount of viscosity modifier (VM) to limit this fall-off in viscosity with temperature, a property known as Viscosity Index or VI. Added to the blend in small amounts, VMs (sometimes referred to as polymers, co-polymers or Viscosity Index Improvers) cause the oil to become more viscous than it would otherwise have been as the temperature increases.

These long-chain molecules can, however, break up under the action of the high shear rates, when loss of viscosity results over time. Oils running at optimum viscosity at the beginning of the race would therefore be seriously 'thinner' at the end of it. So the challenge for the oil blender is to ensure that his blend has the minimum change in viscosity for only the slightest amount of co-polymer, relying more on the properties of the base oil.

Used many years ago to classify motor oils but no longer widely appreciated, you could say that in NASCAR at least, high-VI oils are once more back on track.

Fig. 1 - Variation of viscosity with temperature, and the effect of viscosity index of two 0W-20 oils, each with a kV100 of 8.7 cSt

Written by John Coxon