The two-stroke ring

Love them or loathe them, and despite being virtually outlawed in international motorcycle racing, two-stroke engines are still the main form of propulsion in the world of karting. With far fewer moving parts and power:weight ratios that most four-stroke engine designers can only dream about, the piston ring in a two-stroke engine has an altogether greater task than those in its four-stroke cousin. Not only does it have to seal the combustion chamber at much higher engine speeds and cope with an increased heat flow (one bang per revolution as opposed to one bang per two revolutions for the four-stroke), it has to do all this and cope with crossing both inlet and exhaust ports and be exposed to the full heat of the exhaust gas as well.

Love them or loathe them, and despite being virtually outlawed in international motorcycle racing, two-stroke engines are still the main form of propulsion in the world of karting. With far fewer moving parts and power:weight ratios that most four-stroke engine designers can only dream about, the piston ring in a two-stroke engine has an altogether greater task than those in its four-stroke cousin. Not only does it have to seal the combustion chamber at much higher engine speeds and cope with an increased heat flow (one bang per revolution as opposed to one bang per two revolutions for the four-stroke), it has to do all this and cope with crossing both inlet and exhaust ports and be exposed to the full heat of the exhaust gas as well.

If all this wasn't enough, while every effort is made to ensure the cylinder bore - the barrel, in two-stroke parlance - is perfectly round, the introduction of intake ports, scavenge ports and exhaust ports in the side of it will combine such that even with the best technology available, the bore will be far from cylindrical in operation. And in crossing such chasms, the movement of the ring and the pressures around it will exert instantaneous changes to the radial and tangential forces never experienced or even considered in the four-stroke.

Pegging it in the groove at least prevents ring rotation and stops the possibility of the outer ends springing out and hitting the edge of a port as it passes. But in doing so the ring still needs to be free to move both in and out and up and down in the groove. Drilling the hole for this steel peg in an aluminium piston is therefore a critical operation - slightly too large and although fitting securely when cold it risks falling out at operating temperature; too small and the problem is one of assembly. No wonder aftermarket piston manufacturers are rarely keen to offer such pistons.

The main issue with two-stroke rings, however, is one of lubrication. Since such engines have no crankcase lube, oil to the piston ring(s) has to be transferred within the fuel, so for it to interfere as little as possible with combustion it has to be as sparing as possible. Oil in the fuel/oil mixture lubricates the bore from the bottom, while once in the combustion chamber and in the moments immediately before combustion it lubricates it from above.

Incomplete combustion of this oil will introduce carbon and varnish into the ring groove, causing a phenomenon also seen in some diesel engines - ring sticking. This is when the build-up of carbon and oil varnish condenses on the walls of the ring groove, preventing the free movement of the ring in its groove.

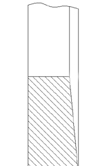

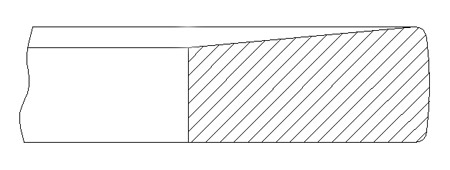

In competition units this is not normally a problem, since regular removal of the cylinder head and barrel is commonplace and the ring or piston regularly cleaned or replaced. In road-going or motocross applications, where two rings are used (as opposed to the single ring piston of the competition unit), rings using a keystone cross-section are often recommended. These have the upper surface of the ring at a small angle to that of the lower face. Seldom more than a 6-7º taper, this cross-section enables gas to get move easily behind the ring to push it towards the cylinder wall, while at the same time the action of the ring moving in and out cleans the ring groove and substantially prevents this build-up in the first place.

Despite now only regularly seen in karting, the two-stroke engine represents a totally different challenge to the piston ring manufacturer.

Fig. 1 - Keystone ring cross-section

Written by John Coxon