Thumpety-thump

Never underestimate the power of nostalgia. For example, the quality of the exhaust noise of a performance car can make all the difference to the enjoyable experience of owning and driving a vehicle, particularly if that vehicle is of a certain age. The sound of the exhaust echoing off dry stone walls on a cool summer’s evening, for instance, or its crackle under a trailing throttle all bring back many fond memories of a now-distant youth.

Little wonder then that vehicle marketeers, all too keen to tap into our collective psyche, are now trying hard to rekindle those feelings by offering vehicles which, while modern and therefore refined in all other respects, have reproduced those little characteristics that make us reflect back. One UK car manufacturer recently introduced a new sportscar that ‘pops’ and ‘bangs’ profusely – deliberately so if desired – on a closed throttle. And now camshaft manufacturers are in on the act by designing cams that make you think of race engine idle quality with roadcar tractability, all using modern hydraulic roller technology produced for more mundane reasons. Generally referred to as ‘thumper’ camshafts as a result of the ‘thumpety-thump’ sound generated at idle, their design is a little more considered than you might think.

So what factors did the cam developers take into account, and which characteristics did they investigate to generate the right aural quality for their customers?

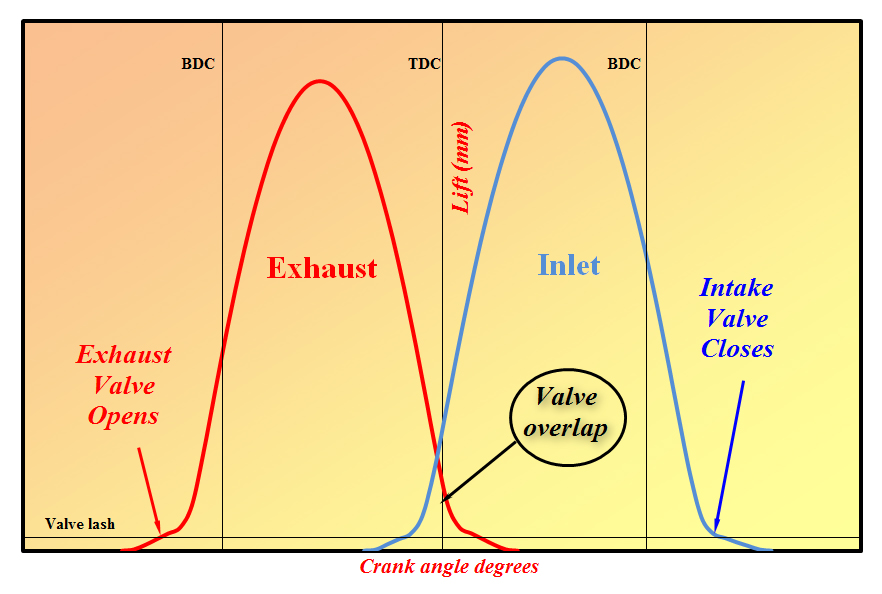

First they analysed a typical race cam and looked at how the interaction of the timing and speed of the exhaust opening position contributed to the volume of the sound and tone of the exhaust note. They reasoned that the sound of the exhaust emanates from the point when the exhaust begins to exit the combustion chamber, with the pressure dropping rapidly and combustion still taking place.

Next they looked at the intake valve closing point. This is traditionally the most important valve event in the cycle since it governs the amount of air to be trapped in the cylinder and which can be burned to create power. Early intake closing traps more air at low speed, whereas later intake valve closing is more effective at higher engine speeds. The correct selection of these optimises the power band to produce a lazy tractable unit or one that is a free-revving thoroughbred race engine waiting to be unleashed.

However, the third area they looked at is what power unit engineers refer to as the valve overlap, and is the area where what might have otherwise become an out-and-out race unit had it not been for a slightly different way of thinking. The overlap period in any engine is the time between the exhaust valve fully closing and the intake valve beginning to open. With both valves open, the intake charge can pass through the combustion chamber and help scavenge the exhaust gas, as in a race engine. Too much overlap can therefore cause an engine to run unevenly and misfire at idle speeds, but when not to excess it can give the characteristic loping sound much associated with a race engine. In researching this part of the profile, designers found that the shape of the overlap (and not just the duration) was equally important, and by carefully profiling the closing and opening ramp the right noises could be made.

Thus in opening the exhaust valve at the correct point, reducing the overlap compared to a race engine and closing the intake earlier, the ‘thumpety-thump’ sound could be reclaimed.

And if you ever want to be converted just go out and listen to one.

Fig. 1 - The ‘thumpety-thump’ cam

Fig. 1 - The ‘thumpety-thump’ cam

Written by John Coxon