Torque tensioning

The proper pre-loading of cyclically stressed fasteners is crucial to their performance. By pre-load, I mean the tension applied to a fastener through tightening before any service loads are applied. If we are to optimise the design of the fastener for minimum mass, this is an especially important point. If the load is too great, we will overload the fastener or the joint; if it is too little, we may fail the joint through separation.

The proper pre-loading of cyclically stressed fasteners is crucial to their performance. By pre-load, I mean the tension applied to a fastener through tightening before any service loads are applied. If we are to optimise the design of the fastener for minimum mass, this is an especially important point. If the load is too great, we will overload the fastener or the joint; if it is too little, we may fail the joint through separation.

Of course, in optimising the design of any given fastener, other factors such as the design of the joint components and materials selection play an important part, but one of the main causes of fastener failure, or the failure of the fastener/joint system to do its job properly, is poor selection and application of pre-load.

What might surprise you is the fact that the method by which the pre-load is applied can affect the design and mass of the fastener, because the differing methods by which the load is applied have varying levels of uncertainty associated with them.

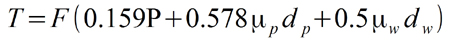

There are two basic steps for the design engineer to consider - calculation of required pre-load, and determination of how the pre-load is applied. For this article, we will consider the application of pre-load by torque tightening alone. The relationship between force and torque is:

Where:

P is the pitch

µp is the coefficient of friction acting at the pitch diameter of the threads

dp is the pitch diameter of the thread

µw is the coefficient of friction acting at the nut-washer or bolt underhead-washer contact

dw is the mean effective diameter of the nut-washer interface

The relationship can be found in a number of books, notably the technical fastener manuals by Bickford*.

While the geometric elements of the equation are simple to measure, read from a drawing or table or calculate, there is considerable uncertainty in the coefficient of friction, and there is also inaccuracy in the application of torque using a torque wrench.

There are tables that give coefficients of friction for various combinations of materials, but roughness and choice of lubricant play a significant role which such tables do not account for. The number of times the joint has been tightened also has an effect. Some lubricants have been developed that are specifically aimed at providing a consistent relationship between torque and pre-load in fasteners.

Bickford estimates significant scatter of pre-load for a given tightening torque: ±30% of design pre-load for a run-of-the mill hand torque wrench and unlubricated fasteners, but this improves to only ±20% when using high-quality tools and lubricated fasteners. Fortunately, with the availability of specific fastener lubricants, as well as better tools and more consistent fasteners than were used for Bickford's experiments, we can expect to improve on these figures. So, why do we continue to use torque tightening as the most common method of pre-loading bolted joints? The answer lies in the simplicity of the method, the relatively straightforward calculations and the availability of good-quality torque wrenches.

* Bickford, J.H., "An Introduction to the Design and Behavior of Bolted Joints", Marcel-Dekker, 1981, ISBN 0-8247-1508-X

Fig. 1 - Good-quality torque wrenches are essential, as is regular calibration, if pre-load scatter is to be minimised

Written by Wayne Ward