Against all odds?

As described in a previous article under this keyword, there are many interesting engines that have their origin in amateur racing series. As mentioned, one of the technically most open motorcycle racing classes is the Supermono, and although this series is not as active and 'hot' as it was in the late 1990s, there are still many great single-cylinder race engine projects riding around.

The engine that is the focus in this article has already been described to an extent in the article referenced above, the self-engineered hybrid 1300 cc by John Ellwood from Sweden. Although the swept volume of 1300 cc does not comply with the rule book, the maximum permitted being 800 cc single-cylinder engines, the Nordic Supermono organisation has granted it permission to race in the Nordic Supermono Racing series next year. This is good news but at the same time it means a lot hard work to get the engine ready for the first race, which is in less than a year from now - remember, the engine is still at the early manufacturing stage.

What is it that is so interesting on this engine? Apart from the fact that it can be seen as a combination of a two-stroke and four-stroke engine - pumping its crankcase volume, as a two-stroke engine does, into the combustion chamber - I believe the reason is more to do with the story behind its creation, as it is a perfect example of persistence. When an average man without any background in engineering can create an unusual engine (the existing 500 cc hybrid) and then has the idea to make a somewhat bigger version, no less than 1300 cc, and then believes fully that this engine will work, you could call that madness. And that might prove to be the case when the bike fires up for the first time - but still, what an adventure.

Let's look at some engine data. With a bore of 118.5 mm and a stroke of 121.5 mm, the swept volume is a gigantic 1339 cc. On the earlier, 500 cc hybrid, the intake plenum pressure was measured at 6 psi, meaning it could almost be considered a 2.0 liter engine. With a compression ratio of 13-15:1, the health of the piston system itself will be the first challenge. For this engine a one-off piston is on order from a well-known supplier, to whom Ellwood has provided his thoughts on the piston, and which for its size alone will be an interesting project for the company.

In order to keep charge temperatures down as much as possible, water spray will be injected into the crankcase, together with the required two-stroke lubrication, and the charge will also need to pass the intercooler on its way to the combustion chamber. The trade-off between temperature and pressure loss will not be too difficult in this case; pressure loss will need to suffer in order to keep temperatures as low as possible. The reason why fuel is not injected early on as well is that the small-end bearing, which is nothing more than a bronze spec bush, can't survive it, so the fuel is being injected at the traditional location, just before the intake to the cylinder head.

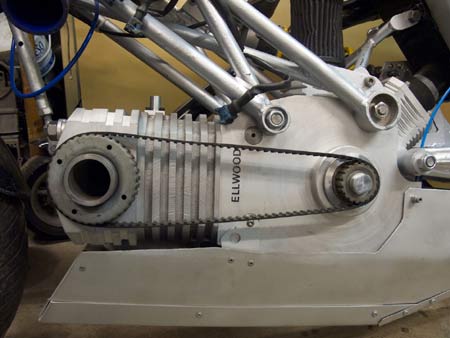

Also, the cylinder head is a piece of craftsmanship, produced out of billet aluminium. Since the cylinder head intake and exhaust are of the rotary type, a two-piece head could be designed, giving easy access to machine the coolant jacket into the two cylinder head pieces. Sealing is achieved by a machined groove, combined with a fluid sealant, simple as possible. Sealing between cylinder head and cylinder liner is done by a flat copper ring.

In talking about this engine, Ellwood told me in all honesty that he had no background in engine design whatsoever, meaning that a couple of dimensions on this engine have room for improvement. For example, with a con rod length of 200 mm, the length-to-stroke ratio is a minimal 1.65:1, something that could have been chosen more optimally to a ratio of 2:1. Since the height - perhaps in this case it's better called length - of the engine is limited by the front wheel, future changes could include decreasing the stroke and increasing the con rod length. For a ratio of 2:1, this would lead to a swept volume of about 1150 cc, which is still massive for a single cylinder.

The engine has a horizontal cylinder, which will surely lead to interesting driveability, especially since the bike will not have a gearbox. The idea is that the massive torque of the engine, combined with a robust but sensitive clutch (which Ellwood is still searching for, by the way) should provide sufficient driveability between minimum and maximum speeds on the racetrack. Again this confidence comes from the earlier 500 cc bike, which Ellwood has also ridden without a gearbox. Quite a challenge.

Is it sane, to create an engine this different? Probably not, but sometimes the challenge of the attempt provides enough food for thought for further steps - perhaps not by the designer as such, but by others. It is ideas and initiatives like this that have enabled the engineering world to get where it is today, and I think Ellwood deserves the opportunity to ride his creation in the Nordic racing series next year. Until then, I wish him success with the challenge of getting there.

Fig. 1 - Right-hand side view of the racing motorcycle, horizontal cylinder and no gearbox, just the clutch for driveability

Fig. 2 - View of the cylinder head, using a rotary-type intake/exhaust valve

Fig. 3 - Left-hand side of the engine, belt-driven rotary valve

Written by Dieter van der Put