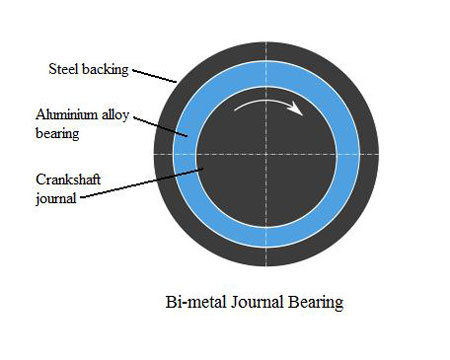

Bi-metal Journal bearings: Materials and construction

Traditional main bearing construction is based on a three-layer bearing made of a steel backing, a hard mid layer and a thin overlay of a soft material.

Traditional main bearing construction is based on a three-layer bearing made of a steel backing, a hard mid layer and a thin overlay of a soft material.

The bi-metal bearing is constructed of only two layers, consisting of a steel backing with an inlay of an aluminium alloy. Typical bearing materials used in the construction of bi-metal bearings are a combination of the following materials: Tin, silicon, lead, copper and aluminium. The bearing material may sometimes be described as aluminium-silicon. The silicon is what bearing manufacturers have determined make aluminium a preferred material for modern bearing applications. The small particles of silicon, are finely and evenly dispersed throughout the bearing material, and since it's an alloy, it can maintain its properties throughout the entire bearing thickness resulting in a more consistent, reliable performance.

Debris is a major cause of bearing failure and it can be left over from machining operations or due to wear of the component parts. Debris can get trapped between the journal and the bearing surface and lead to damage of the bearing surface and/or scoring of the journal, and could ultimately lead to failure. Debris is an important point with bi-metal bearings due to issues over embeddability.

Bi-metal bearings are considered harder than tri-metal bearings. The surface of the bearing contains hard and soft areas where the soft areas allow embeddability, whilst the harder areas do not. Embeddability is the ability to embed hard particles and foreign debris within the bearing material. However, due to the hard and soft nature of the bearing surface, it is possible for debris to become trapped between the bearing surface and the journal leading to wear. Therefore, to counteract this effect, the bi-metal bearing is machined with micro-grooves to retain the hard particles, these particles eventually being washed away by the lubricating oil.

Note that the different combinations and quantities of alloying materials, as used by the different manufactures, will provide different bearing characteristics. Whereas the aluminium-silicon alloy may produce a hard bearing with partial embeddability, another aluminium alloy mix may provide a bearing that offers much improved embeddability and higher load carrying capabilities.

Bi-metal bearings do possess conformability, which is the ability to adjust to minor misalignments during assembly.

In general tri-metal bearings are said to have a greater load carrying capacity then aluminium bi-metal bearings. In terms of bearing selection, that is, whether to use tri-metal or bi-metal bearings, it may come down to how much load the bearings have to withstand and the life expectancy of the bearings. For example, bi-metal journal bearings may be used in a high load application for a short period of time; for example a drag car, having one or two runs. If high load carrying characteristics and longevity are required, then tri-metal bearings may be selected. This example of bearing selection is not meant to be exhaustive, but to illustrate that a trade off between the two bearing types has to be made. Note also that cost will also be a factor.

In comparing bi-metal to tri-metal in severe load applications, there will no doubt be some cases where the bi-metal bearings will outperform those of tri-metal. If the roughness of the sliding surfaces is reduced, the load carrying capacity of the bearing is increased. Hence concentrating on bi-metal bearings in this way, could provide load carrying benefits.

The future trend for journal bearings may be headed toward the bi-metal type, but tri-metal bearings are still in demand. In all probability, bi-metal and tri-metal journal bearings may continue to co-exist for quite some time.

Aluminium alloy journal bearings are not new. What has propelled them forward are possibly the latest methods of manufacture and the inclusion of materials such as silicon. Bi-metal bearings have the benefit of higher melting points and greater fatigue surface strengths, than tri-metal bearings.

Fig. 1 - Typical bi-metal journal bearing

Written by Eric Smart