Carburettor progression

Back when petrol in the UK cost the equivalent of about 30p in current money and the Beatles were top of the music charts, the fixed-choke carburettor – particularly that of the DCOE – was most definitely king. Affectionately known as ‘Webers’, and more often than not a replacement for the constant depression SU or Stromberg, the throaty induction roar of the single-choke-per-cylinder device was the thrill for many, even it often yielded no more engine power. Carburettor sizes, chokes, main jets and emulsion tubes were the talk of the day, but to my memory nobody ever seemed to talk about ‘progression’.

Defined as the movement from one state to another, the progression of a fixed-choke carburettor is the transition stage between engine idle and the point when the main fuel system comes into play, and in my opinion is the one area in tuning a carburettor that is the least understood. The difference between an engine that is ‘tuned’ to give to give good progression and one that is less well tuned is the difference, in vehicle driving terms, between ‘chalk and cheese’. While both can produce the same ultimate performance, the former can be a delight to drive while the latter is a complete dog.

On all fixed-choke carburettors – not just those with a single choke per cylinder – at the engine idle setting the throttle plate will be positioned such that only a small amount of intake air will bleed past into the engine. Mixed with fuel metered through the idle fuel jet downstream of this plate, when burned, the power produced will be just enough to overcome engine friction at this idle speed.

As the throttle is slowly opened, the pressure difference across the throttle plate will fall and the air speed into the engine will increase. During this period, however, the increase in airflow will not be enough to bring the main fuelling system – the auxiliary venturi, main jet, emulsion tubes and air correction jets – into play. If not corrected in some way, the lack of fuel from the now not so effective idle system will make the engine run lean, stumble and possibly even misfire. To the driver, the engine may feel unwilling or unresponsive when moving away from rest and lead him (or her) to complain about ‘flat spots’ or having to ‘rev’ the engine much more at pull-away.

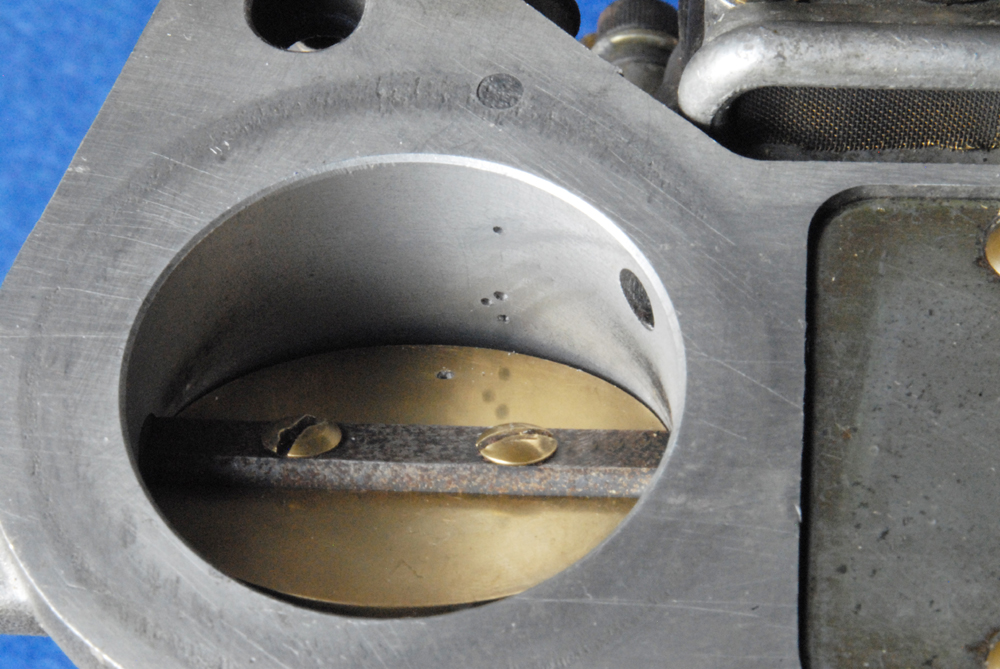

To combat this, a small number of tiny progression drillings are introduced into the wall of the carburettor, slightly away from that of the idle fuel drilling, to increase the flow of fuel. Linked to the same circuit as that of the idle fuel circuit, as the throttle plate progressively opens then each drilling at a time is uncovered and more fuel drawn into the airstream. Usually consisting of two or perhaps three holes of differing sizes, by the time the last one has been uncovered the main jet circuit will be starting to function, making both the idle and progression circuits redundant, since the depression in the port compared to that in the carburettor float chamber will by now have almost disappeared.

It’s very much a trial-and-error procedure, and if you drill these holes in the wrong place then the carburettor could be rendered scrap – which in a funny way could be why nobody ever talked about it at the time.

Fig. 1 - Three progression holes just uncovered by the throttle plate. The single hole above is for the idle fuel

Fig. 1 - Three progression holes just uncovered by the throttle plate. The single hole above is for the idle fuel

Written by John Coxon