Tight times!

The most common aspiration of just about all power unit engineers is that of greater engine performance. Better fuel economy, improved toxic emissions or simply better torque over a wider range of operating speeds - much of it but certainly not all - is down to the selection of the cam profile and its timing.

The most common aspiration of just about all power unit engineers is that of greater engine performance. Better fuel economy, improved toxic emissions or simply better torque over a wider range of operating speeds - much of it but certainly not all - is down to the selection of the cam profile and its timing.

In the search for greater efficiency, compression ratios have increased in recent times, resulting in much smaller, more compact combustion chambers. To avoid mechanical mayhem and yet still flow ever-higher amounts of intake air, valve lifts have therefore become higher over a shorter period of time. This would seem to be an unalterable fact of life and applies equally to production road-going engines as their even more highly refined race engine brothers.

Helped by more reliable knock sensor technology, the knock-safe compression ratios of 8:1 in two-valve production engines of earlier years have now morphed into the knock-sensitive 10:1 (or even greater) compression ratios of modern four-valve units. But when it comes to extracting even more power from these units some enthusiasts still seem to think in terms of changing only the camshaft.

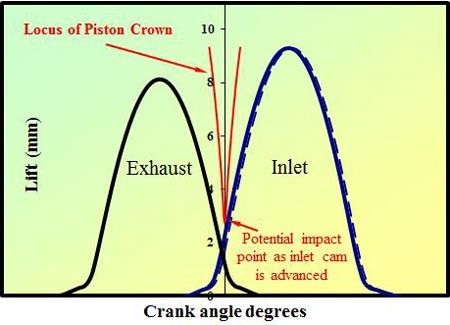

A trick used by all engine designers to boost performance at high engine speeds is to design in a certain amount of 'valve overlap' - that period in the engine cycle when both exhaust and inlet valves are open at the same time. To the casual observer this might sound rather contradictory - both filling and emptying the cylinder at the same time - but by carefully sequencing events the extraction effect of the pulsating exhaust can draw into the cylinder a greater amount of fresh charge. The greater the valve overlap the greater the potential for improved performance at higher engine speeds, but since the piston crown is rapidly approaching its maximum height at top dead centre the ever-present threat of mechanical contact between piston and valves has to be taken into account.

In production engines where the combustion chamber will have been finely honed for optimum performance and emissions, unlike earlier times, the valves will come very close to the piston towards the top of its travel. Cut-outs in the piston crown, if they exist at all, will be very small since they can harbour unwanted and unburned hydrocarbons.

Any significant change in the camshaft lift to gain extra airflow will therefore require larger pockets, which will in turn reduce the engine compression ratio. Increasing the duration of the cam will also almost certainly risk the whole profile needing to be advanced, in the case of the exhaust cam, or retarded in that of the inlet. In both cases, such a move is likely to create very little in the way of increased top-end power at the sacrifice of that much lower down in the engine speed range.

Perhaps more a testament to the skills of the power unit engineer over the years, the upgrading of a production engine by replacing the camshaft alone, other than in race formulae where it is the only option, is likely to disappoint.

Fig. 1 - Valve-to-piston crown clearance

Written by John Coxon