Bushless small ends

When we come to describe a 'traditional' racecar con rod for a four-stroke engine, we would imagine a split rod with a bushed small end (or at least many of us would). The bushed small end has been with us for many decades, but the bushless steel con rod is becoming more popular, and bushless rods are a possibility in a number of other materials. As reported in the con rods 'Focus' article in Race Engine Technology (issue 48, August 2010), some rod suppliers have been supplying bushless con rods for over 20 years.

When we come to describe a 'traditional' racecar con rod for a four-stroke engine, we would imagine a split rod with a bushed small end (or at least many of us would). The bushed small end has been with us for many decades, but the bushless steel con rod is becoming more popular, and bushless rods are a possibility in a number of other materials. As reported in the con rods 'Focus' article in Race Engine Technology (issue 48, August 2010), some rod suppliers have been supplying bushless con rods for over 20 years.

There are a number of advantages to running a con rod without an interfered small-end bush. Obviously there is a lower parts inventory at the rod manufacturer for a start, but there are a number of good engineering reasons for looking to a bushless con rod.

There is a small weight saving gained from dispensing with the bush itself. The small end of the rod can simply be maintained in section, but brought closer to the pin axis. However, it can be further optimised as it no longer has to cope with the stresses induced by the interference fit of the bush, in addition to any service loads. The section of the small end can safely be reduced while still staying within safe working limits of stress.

Owing to the fact that the small end is now smaller, we might choose to push the pin bore higher in the piston and run a slightly longer rod. One advantage of this is that the angularity of the rod is decreased, and piston-to-bore friction can be reduced as a result. A second advantage is that secondary forces are reduced; these are a function of the crank radius-to-rod length ratio.

Alternatively, we can simply re-optimise the design of the rod in the light of having a lower-mass small end. A consequence here is that the crank counterbalance mass can also be reduced. It is unlikely that many people would re-optimise all of these components, having decided to equip their engines with bushless con rods, but for those in the business of regularly designing bespoke race engines, such detailed re-optimisation is possible and is an attractive prospect, even when overall engine weight is controlled or where component mass is controlled.

A wide range of materials have been used with success for bushless con rods, including metal matrix composites and aluminium alloys. Materials such as aluminium and titanium can suffer if an interfered bush does not go in 'cleanly'. If there is pick-up or galling when the bush is interfered, this can act as a stress raiser and therefore the factor of safety against failure needs to take some account of this possibility. Attempts to prevent such damage during fitting involve use of special lubricants, or coatings for both the outside diameter of the bush and the bore of the small end.

In addition to these reasons, the rod should be simpler, quicker and less expensive to make. There is a reduction in the number of precision operations involved and a lower parts count, both of which should result in reduced manufacturing time and costs.

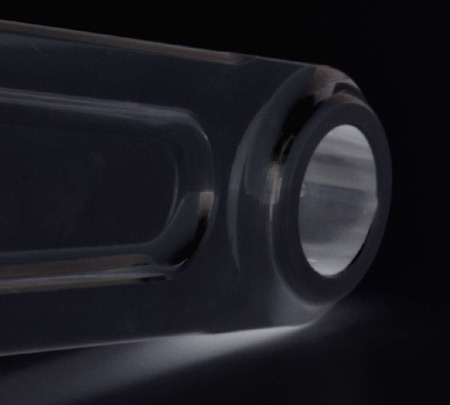

Fig. 1 - Bushless con rods for race engines have a number of advantages

Written by Wayne Ward