Joint face serrations

The matter of how to positively locate the two halves of a conventional split con rod together is one to which there doesn't appear to be a single solution that everyone has adopted. In terms of production cars, the approach of using a controlled fracture is now very popular, and is being applied to stronger grades of material.

The matter of how to positively locate the two halves of a conventional split con rod together is one to which there doesn't appear to be a single solution that everyone has adopted. In terms of production cars, the approach of using a controlled fracture is now very popular, and is being applied to stronger grades of material.

Traditionally, racing rods have had their mating caps located by either the use of small dowel pins, or by ring dowels. To accurately and repeatably locate the two pieces of the rod assembly together, there is a requirement to use a location dowel on each side of the rod. A third option of using slightly interfering location diameters on the fasteners is only generally used where the fastener is used in combination with a nut.

In recent years, new methods of location have become more popular for bespoke rods; precisely machined serrations on the rod and cap locate together to produce a very rigid joint. The advantages are that any shuffling and fretting of the rod split face can be avoided, and there is a possibility to get rid of the location dowels, giving more freedom in the design of the rod.

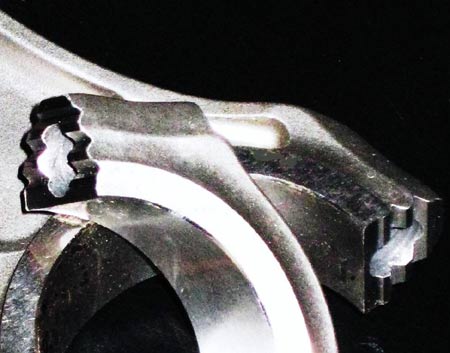

There are two variations on this technique: one is to use straight-cut serrations, similar to a very short section of a rack, and the other is to use curved serrations (see accompanying pictures).

The straight-cut serration can only constrain the cap in a single direction, and so would require further features such as ring dowels or location pins to accurately locate the two pieces of the con rod. Given that the width of the con rod big end generally relies on the two parts of the rod being located precisely, the danger in not providing extra location features is that rod thrust clearance is reduced from design values. The straight-cut serration shown in Fig. 2 has a much smaller number of serrations than the curved serrations produced by another manufacturer. It should be noted that both of these types of serrated joint face are being supplied to and used in high-level motorsport.

Curved serrations constrain the cap from movement in any direction on the split plane of the rod, and so are free of the requirement to use any further location features. There are, of course, an infinite number of ways of arranging the serrations; Fig. 1 shows one solution, with the serrations for each side of the con rod being centred about an axis that is outside the body of the rod.

Providing that the central axes of the curved serrations on each side of the rod are not coincident, the cap can not move in a planar motion or rotate, thus tying down all degrees of freedom. The rod with curved serrations shown is an aluminium rod. Many of us will be familiar with the problems of running two aluminium faces in contact - fretting is a particular problem, which is likely to be mitigated by controlling the very small movement causing this phenomenon.

Figs. 1 and 2 - Two options for joint face serrations are shown. Both curved and straight-cut serrations are currently used in high-level motorsport

Written by Wayne Ward