The slide throttle

As a lifelong student of automotive technology I never fail to be amazed by the inventiveness of the human mind, and one of the best places to demonstrate that is to look at patent applications down the years. Many inventions of course never come to anything, for various reasons. In some cases the principle has been patented just in case there is a need for it in the future, and to prevent others from adopting the same idea and patenting it themselves. An example I came across recently was that of the slide throttle.

Famous – or perhaps infamous – for its use on many race engines in the 1960s and ’70s, the slide throttle has much to recommend itself, although at the same time much to suggest you shouldn’t even think about using them at all. As a rule they are difficult to package, prone to jamming – normally wide open – and almost impossible to produce a smooth progression from fully open to fully closed without some kind of ‘trick’ mechanical linkage. Put against this, when fully open there is no throttle spindle to impede airflow, which is perhaps the reason why many inventors keep coming back to this design when inventing new and apparently innovative uses of controlling engines.

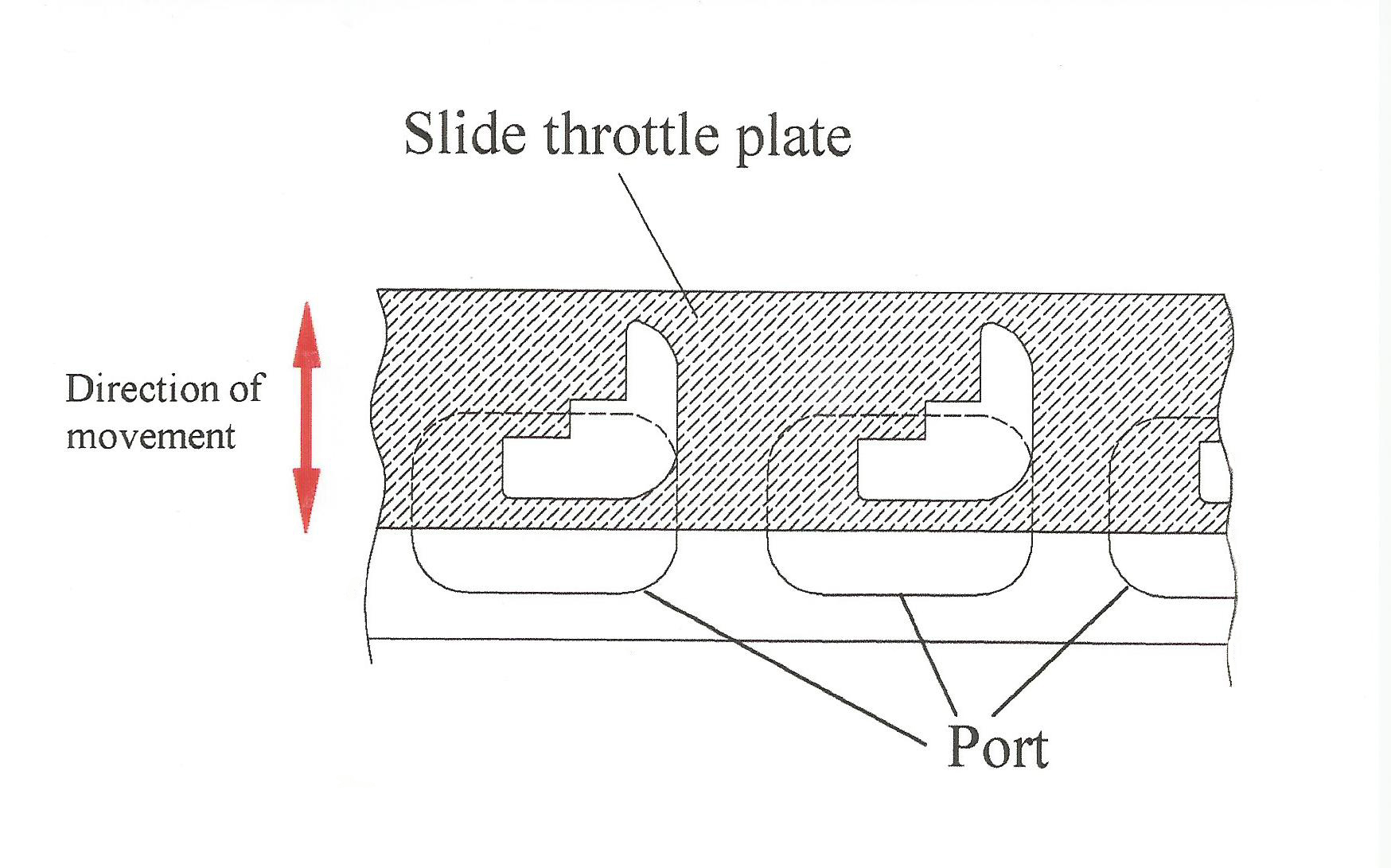

One of these innovations I discovered recently was a device to introduce swirl into the intake air immediately before it passes into the cylinder. Of 1998 vintage, the idea was that instead of sliding the throttle plate back and forth, the plate moved up and down. By biasing the flow relative to the centreline of the intake port, swirl could be introduced in varying amounts according to the demand of the engine – high swirl at low flows gradually reducing as full power was demanded. Novel but I’m not sure of the real benefit. Nevertheless, the manufacturer saw a benefit in preventing anyone else from using the idea commercially.

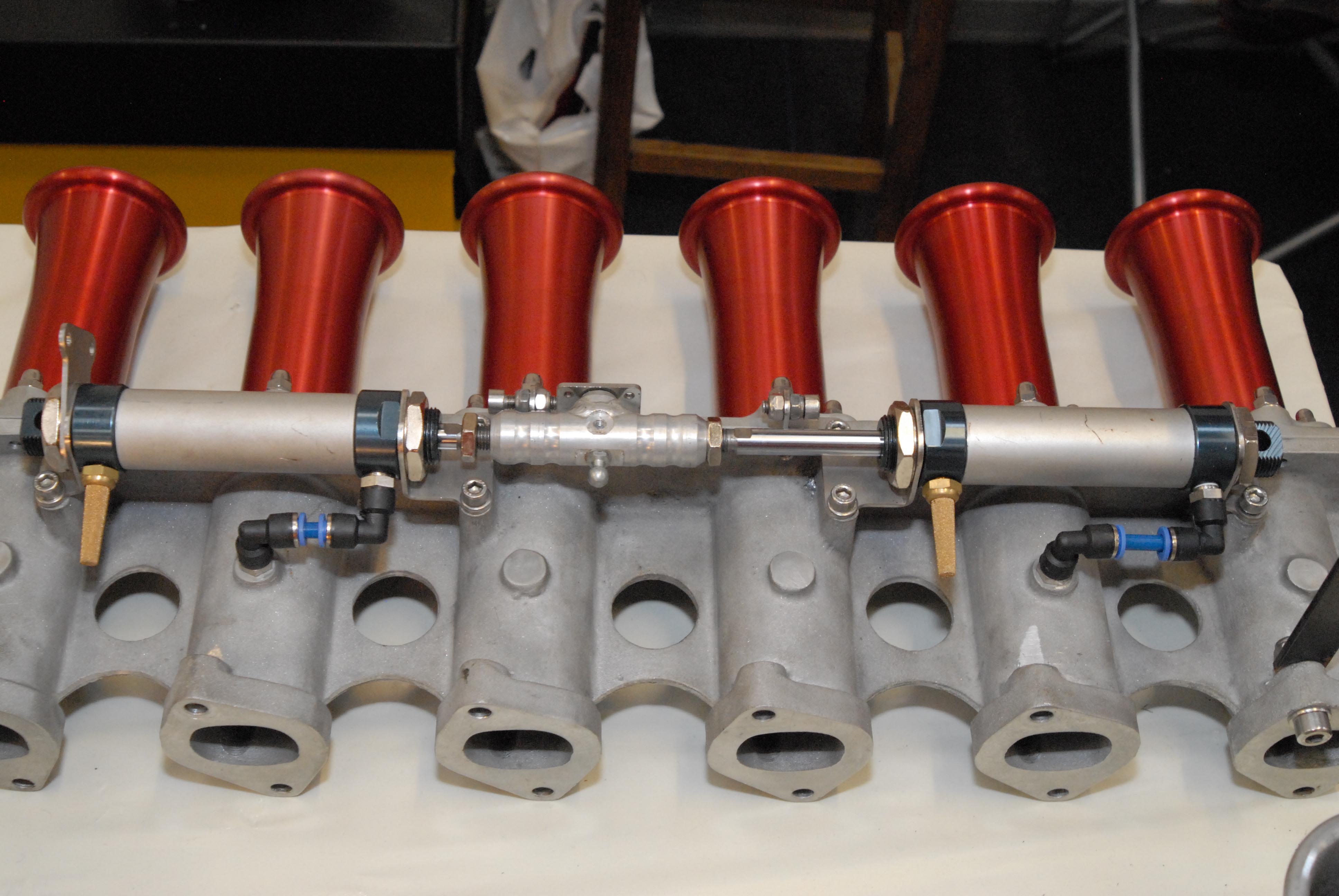

Another idea I saw recently linked to the use of slide throttles and one that is said to be fully patented is the device shown in Fig. 2. Perhaps the biggest problem encountered by drivers using slide throttles is the amount of pedal load required to open the throttles in the first place. This is a result of the return spring tension necessary to close the throttle and the high friction between plate and its guide when used for long periods of time which can be tiring to the driver.

What this particular invention tries to do is to use the vacuum behind the throttle plate at part-load when connected to a cylinder as a kind of servo device to open the throttle at much lighter throttle pedal loads that would otherwise be the case. It’s clearly an interesting idea and one that I can see would appeal to many a classic engine owner-racers with a slide throttle system.

For the rest of us who prefer the more progressive nature of the traditional butterfly system, however, mere memories of sticking throttles is enough to send shivers down our spines.

Fig. 1 - 1998 patent application

Fig. 1 - 1998 patent application

Fig. 2 - Slide throttle servo system

Fig. 2 - Slide throttle servo system

Written by John Coxon