Cotton-based filters

If you’ve ever examined the contents of the dirty side of the air filter of your daily transport you don’t need me to emphasise the importance of the filter on the engine air intake. Grit, dead leaves and even quite large insects can all easily be found scattered inside the entrance to the airbox, so in contrast to the ‘clean’ zone at the inner side of the filter, if ever there was a case for including an air filter on all engines – particularly those for competition – than surely that must be it.

But the technology of separating engine intake air from, well, just about everything else hasn’t changed much over the years. One option is the physical barrier – a sieve of some description or other consisting of a series of holes through which only the smaller particles can pass. Simple and therefore popular, air filters of this type need to have much larger surface areas to avoid high pressure losses across the filter as the amount of dirt captured increases.

The other option, which is popular in much older vehicles and finding traction again in the high-performance aftermarket, is to exploit the properties of certain types of oils, and in association with the barrier method it can deliver some of the most efficient types of filter. Years ago, after changing his engine oil, your grandfather would have then changed the oil in his air filter. Cleaning the metal gauze inside the air filter body with gasoline and coating it again with one of the vegetable-based oils available at the time, this oil – being surface active and positively charged – would stick to the metal gauze and attract dirt. The labyrinth of gauze would ensure that the larger grit particles would have dropped out and been captured by the oil in the base of the filter, letting the ‘clean’ air pass through into the engine.

Now of course we have much more efficient barrier systems and, when used in conjunction with the properties of modern types of oil designed purely for the purpose, air filters can be produced that are not only highly efficient but are cleanable – and, or so the manufacturers maintain, can last the lifetime of the vehicle. The barrier part of the filter consists of a couple of layers of woven cotton material, the first having a much looser weave than the second. While the first layer traps all the large particles, the smaller particles pass through and are trapped by the second layer.

To give strength to the assembly, the cotton filter material is encased in steel gauze which, when coated with this special oil, attracts dirt even before it gets to the filter medium. Pleated to create a large surface area and working together as a system, the assembly can therefore hold much larger quantities of dirt before the pressure drop across it demands cleaning. Not only does the oil attract the dirt, when diluted in something like isopropanol and sprayed onto the cotton gauze, the action on the cotton is to tighten the weave such than particles greater than 5 microns will not pass.

Something old, something new, but together they produce a formidable combination.

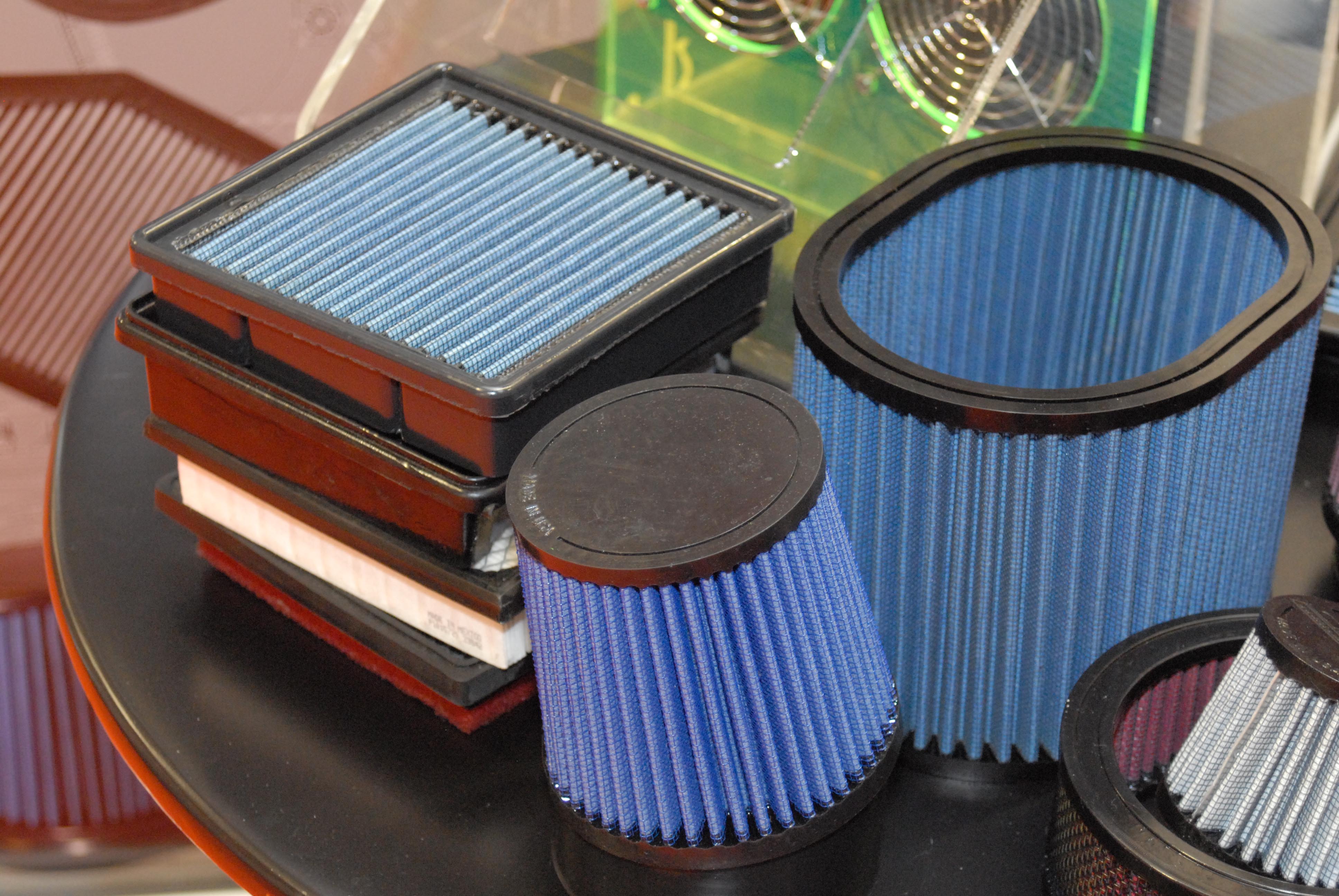

Fig. 1 - Just a cotton-picking filter

Fig. 1 - Just a cotton-picking filter

Written by John Coxon