Conventional H-Gate manual shift gearbox

The conventional H-gate manual shift gearbox, a universal feature on all race cars until about 20 years ago, is actually a highly counter intuitive control device...

The conventional H-gate manual shift gearbox, a universal feature on all race cars until about 20 years ago, is actually a highly counter intuitive control device...

Consider the conventional passenger or race car control system:

First, we have the right hand ‘throttle’ pedal – if you press with your foot you go faster, release your foot and you slow down – logical enough. The second pedal, well, if you want to slow down a lot faster, or in an emergency, press this, we’ll call it the Brake… Sooner or later you will need to deviate from a straight line, and so we provide a ‘wheel’ in front of your seating position... rotate it to the right and you go… right. And vice versa.

But now consider the remote lever, which goes up and then down through a gate, then side to side, up and down again, and furthermore needs to be in a different – although not necessarily the same – part of the gate depending on your road speed, engine revs, and type of manoeuvre... And furthermore, it needs a third pedal to control it before operation… Who dreamt that up?

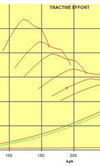

Given that some form of multiple, intermediate gearing between engine and road wheels is necessary with an internal combustion engine, it’s hardly surprising that since the dawn of the motor car alternative forms of automating the change process have been pursued.

In the race car, the issue has been more one of the impact on this process on the cars performance rather than of difficulties in executing it – although for many years ‘transmission’ failure originating from the pilot’s desperate attempts to shift from one gear to another in the minimum possible time were a common cause of race car unreliability.

In the modern Formula One car we have arrived at a situation where the ‘twin clutch’ transmission is used. We have arrived at this via automated clutching and declutching of a traditional manual shift gearbox using driver actuated microswitches, a solution that future historians will regard as ‘interim’. Whilst these systems can provide a useful saving in the time the lag between applying tractive effort in one gear and then the next, they are as significant in the way that they have removed the ‘driver variable’ in the shift process, and hence increased reliability, particularly when their use spread to endurance racing.

The twin clutch system still operates a traditional manual box – but by providing two clutches to operate non sequential gears, it is possible to have the next gear ‘pre-selected’ with the second clutch almost instantaneously with the current gear being disengaged by the first. Naturally this process is operated by the driver via microswitch.

This is somewhat more intuitive than being presented with an H-pattern gear lever and foot operated clutch pedal, but still falls some way short of full automation.

The use of the torque converter on race cars has been limited over the years due to their weight, complexity, power consumption, torque consuming ‘slip’ and limiting effect on operator override. A notable exception was the unit developed by General Motors in the 1960’s and raced for several years on the Chaparral Can-Am and endurance race cars. It was no coincidence that they were used in conjunction with large capacity engines with a broad range of torque.

Ironically, to find a more appropriate predecessor for today’s twin clutch boxes we need to look back into the pre-War British racing scene, where it was common to see the ‘Wilson’ epicyclic pre-selector box used. The early ERA’s, various Alta’s a number of ‘Brooklands’ specials and others were so equipped. These boxes, although heavy and bulky in comparison even to the crude dog boxes of the day, were popular because they achieved the same end result as the modern Formula One ‘box. No clutch was fitted, but two brake bands used to provide ‘slip’, and allow for pre-selection via a conventional lever which was then actuated when required by stamping hard on a foot pedal in place of the traditional clutch. This was the ‘30s equivalent of a 21st century microswitch and processor unit, and allowed the driver to keep both hands on the wheel at the critical moment, which even then was recognised as a more stable and controllable driving technique.

So, in some respects, after decades of trying very successfully to perfect a crude and counter intuitive system we have come full circle. Another example of the past rewarding study?

Written by Peter Elleray.